Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the world of lifting equipment, manual chain blocks stand out for their simplicity, reliability, and versatility. These devices, often utilized in construction, warehouses, and various industrial settings, provide an efficient solution for moving heavy loads with minimal effort. As John Smith, a renowned expert in lifting technology, once stated, "The efficiency of a manual chain block lies not just in its design, but in the operator's understanding of safety and technique." This underscores the importance of not only choosing the right equipment but also ensuring that it is used safely and properly.

In 2023, selecting the best manual chain blocks requires an understanding of the unique features that make these tools effective for different environments and tasks. Factors such as weight capacity, durability, and ease of use play critical roles in determining which manual chain block is best suited for a specific job. As industries evolve and the demand for safe lifting solutions increases, the market is seeing an array of options that cater to diverse needs.

In this guide, we will explore the ten best manual chain blocks that have set the standard for safety and efficiency this year. Whether you are a seasoned professional or a novice to material handling, understanding the capabilities of these tools will enhance your operational effectiveness and ensure safe lifting practices.

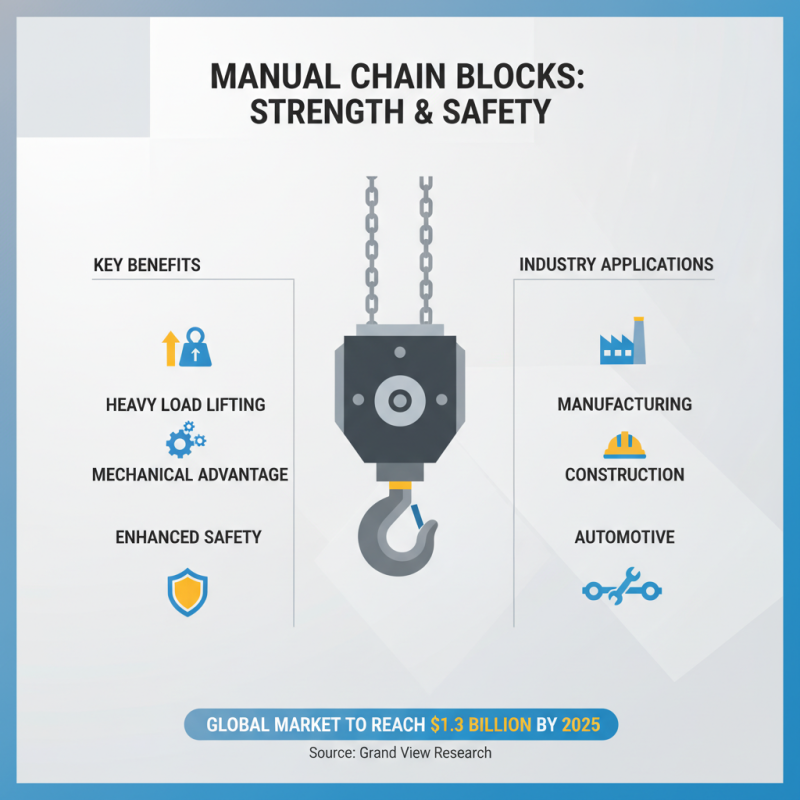

Manual chain blocks, also known as chain hoists, are essential tools in various industries for lifting heavy loads safely and efficiently. According to a report by Grand View Research, the global market for manual hoists is projected to reach $1.3 billion by 2025, highlighting the increasing demand for lifting equipment that combines safety with efficiency. These devices provide a mechanical advantage through the use of a chain and pulley system, allowing operators to lift significant weights with minimal effort.

One of the standout features of manual chain blocks is their simplicity and reliability. They require no electric power, making them ideal for use in locations without access to electricity or in situations where power failure is a concern. Furthermore, the absence of complex electronics means reduced maintenance and longevity of the equipment. The American National Standards Institute (ANSI) emphasizes the importance of using manually operated hoists for specific applications due to their lower risk of mechanical failure compared to their powered counterparts. This reliability translates into increased safety for workers involved in lifting operations, making them an attractive choice for many businesses looking to enhance productivity while prioritizing safety standards.

The versatility of manual chain blocks allows them to be used in a wide range of applications, from construction sites to warehouses. Their design typically includes a safety latch and an overload protection mechanism, which are critical features in preventing accidents and ensuring user safety. This focus on safety is backed by industry statistics, which indicate that properly maintained manual chain blocks can reduce the risk of lifting-related injuries by over 30%. As organizations increasingly focus on workplace safety and efficiency, manual chain blocks continue to play a crucial role in lifting operations across various sectors.

When selecting the best manual chain blocks for lifting tasks, several important criteria must be considered to ensure safety and efficiency. First and foremost, lifting capacity is a critical factor. According to industry reports, manual chain blocks typically range from ½ ton to 5 tons of lifting capacity. A thorough assessment of the specific weight loads encountered in your operational environment can help identify the appropriate block that aligns with safety standards and operational demands.

Another vital consideration is the chain length and material. Industry guidelines suggest that a longer chain allows for more flexibility in handling various lifting heights, while the material should ideally be robust enough to withstand heavy use. For example, chains made from carbon steel or alloy steel are preferred due to their strength and durability. Furthermore, ease of operation and maintenance is essential; models equipped with smooth lifting mechanisms and accessible lubrication points are recommended for prolonging life expectancy and enhancing user efficiency.

Lastly, it is important to evaluate the safety features of manual chain blocks. Many leading safety organizations highlight the significance of features like overload protection and quality braking systems, which minimize the risk of accidents during operation. A well-balanced manual chain block that distributes weight evenly can significantly reduce operator fatigue and enhance lifting precision. Keeping these criteria in mind will ensure that the chosen chain block meets both safety and efficiency standards in a work setting.

When selecting a manual chain block for your lifting needs in 2023, it’s essential to focus on both safety and efficiency. The top manual chain blocks on the market this year have been designed with advancements that ensure smooth operation, durability, and greater load capacities. Key highlights to consider include the construction materials, mechanical advantage, and ease of use. For instance, many of the best models feature robust alloys and innovative gear systems that enhance lifting speed while minimizing user fatigue.

Tips for choosing the right manual chain block include evaluating the weight limits based on your lifting tasks and ensuring compatibility with your workspace. Check for user-friendly designs that facilitate fast setup and operation, and prioritize blocks that offer safety features such as overload protection and secure hooks. Regular maintenance, such as lubrication and inspection, can prolong the lifespan of your equipment and enhance safety during use.

As you explore the manual chain blocks available this year, consider your specific lifting requirements and the environment in which you’ll be operating. This will help you select a block that not only meets your needs but also stands the test of time, ensuring efficient lifting for years to come.

| Model | Load Capacity | Lift Height | Weight | Material | Price Range |

|---|---|---|---|---|---|

| Model A | 1 ton | 3 m | 10 kg | Steel | $100 - $150 |

| Model B | 2 tons | 4 m | 15 kg | Aluminum | $120 - $175 |

| Model C | 3 tons | 5 m | 20 kg | Steel | $140 - $200 |

| Model D | 1.5 tons | 3.5 m | 12 kg | Aluminum | $110 - $160 |

| Model E | 2.5 tons | 6 m | 25 kg | Steel | $150 - $220 |

| Model F | 1 ton | 4 m | 11 kg | Aluminum | $90 - $130 |

| Model G | 3 tons | 7 m | 22 kg | Steel | $160 - $240 |

| Model H | 1.25 tons | 5 m | 14 kg | Aluminum | $110 - $180 |

| Model I | 2 tons | 6.5 m | 19 kg | Steel | $130 - $210 |

| Model J | 1.5 tons | 4.5 m | 13 kg | Aluminum | $125 - $190 |

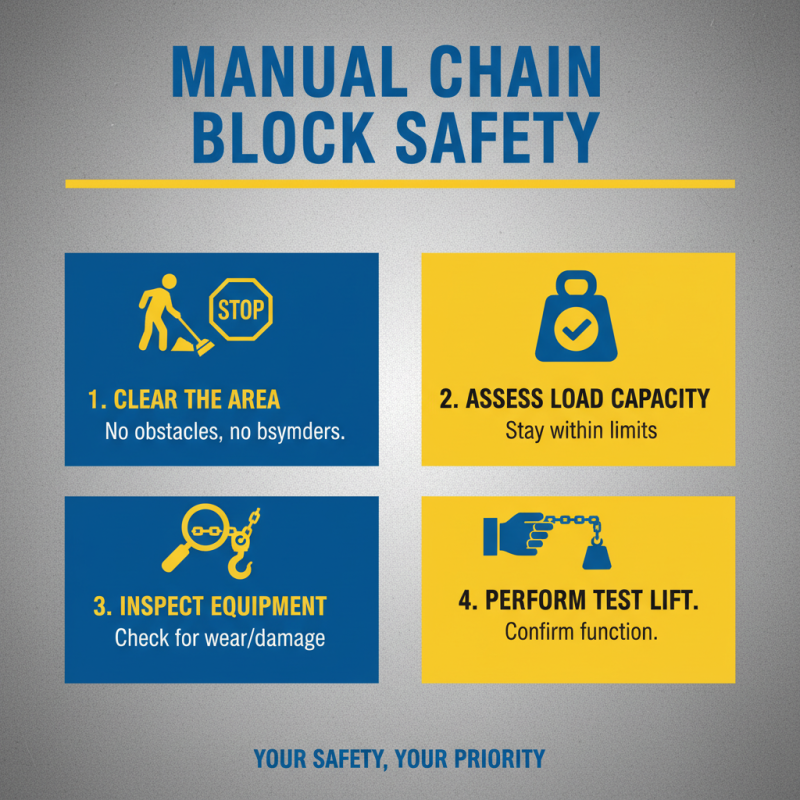

When using manual chain blocks, safety should be your top priority to ensure secure lifting and avoid accidents. Ensure that the area around the lifting site is clear of any obstacles and bystanders. It’s essential to assess the load beforehand and ensure it is within the rated capacity of the chain block. Inspect the chain block thoroughly for any signs of wear or damage, including the chains, hooks, and other components. Always perform a test lift to ensure that the equipment is functioning correctly before lifting the full load.

Tips for safe usage include maintaining a stable footing and using proper lifting techniques to prevent strain. Always use both hands when operating the hand chain and maintain a firm grip to control the lift. Additionally, allow only trained personnel to operate the manual chain block, as they will be more aware of potential risks and proper measures to take. Ensure that all operators are familiar with emergency procedures in case of unexpected incidents during operation.

Lastly, ensure that your lifting environment is well-lit to avoid mistakes. Consider using signal personnel to communicate during the lifting process, as this can greatly enhance safety. Regular training sessions on safety protocols can also empower workers to operate with confidence and responsibility, further mitigating risks associated with manual chain blocks.

Maintaining manual chain blocks is crucial to ensuring both their longevity and operational efficiency. Regular inspection is key; according to industry standards, chain blocks should undergo thorough checks at least once every six months to identify wear and tear. Components such as hooks, chains, and gears should be evaluated for signs of deformation or damage. Data from the Occupational Safety and Health Administration (OSHA) indicates that improperly maintained lifting equipment contributes to a significant percentage of workplace accidents, emphasizing the importance of proactive maintenance.

Lubrication plays a vital role in preserving the functionality of manual chain blocks. The American National Standards Institute (ANSI) recommends using appropriate lubricants on moving parts, as this reduces friction and prolongs the life of the components. Additionally, it’s important to keep the chain and other parts free of debris and contaminants, which can exacerbate wear and lead to operational failures. Manufacturers typically suggest cleaning the equipment after each use, particularly in harsh environments, to mitigate rust and corrosion, key factors that can severely shorten the lifespan of chain blocks.