Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the world of heavy lifting, the "Manual Chain Hoist" remains an essential tool. Renowned expert John Harrison says, “A good hoist can make the difference between safety and disaster.” This emphasizes the importance of choosing the right manual chain hoist.

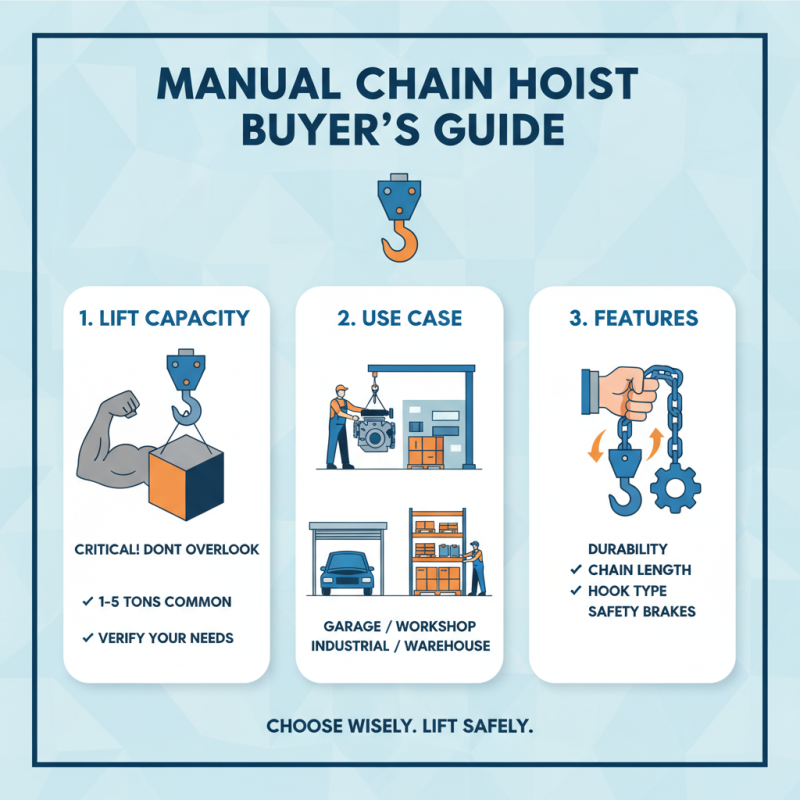

When selecting a manual chain hoist, many factors come into play. Load capacity is crucial. Users should assess the weights they lift regularly. Durability and ease of use are also key. Not all models serve the same purpose, leading to the risk of misuse. An inadequate hoist can lead to injuries or equipment damage.

However, not every manual chain hoist is the same. Some models lack the safety features needed for high-stakes environments. It’s vital to research each option thoroughly. This investment is not just about lifting but ensuring safety for every operation.

Manual chain hoists are essential tools in material handling. They allow for the safe lifting and maneuvering of heavy loads. According to a recent industry report, manual hoists account for about 30% of the material handling equipment market. They are favored for their simplicity and reliability, especially in environments without access to electric power. Their versatility makes them suitable for various applications, from construction sites to warehouses.

Effective use of manual chain hoists enhances safety and efficiency. Operators should be trained to understand load limits. Overloading can lead to equipment failure, which may cause injuries. Regular inspections of the hoists for wear and tear are also crucial to maintain their functionality. A tip: always read load ratings carefully before operations.

In tough conditions, sometimes hoists are misused. Operators may be pushed to lift heavier loads than recommended. This practice can result in accidents. It's vital to always ensure the right equipment is used for the specific task. When selecting a hoist, think about working conditions and load types. Make informed choices based on both safety and performance metrics.

When choosing a manual chain hoist, several key features are essential. First, the lift capacity is critical. Many users overlook this and end up with hoists that can’t handle their needs. Most models can lift between 1 and 5 tons. Verify the weight of items you need to move.

The chain length is another key feature. Typically, lengths range from 10 to 20 feet. Shorter chains can be limiting, while longer ones offer flexibility. Ensure the chain is made from durable materials to avoid wear over time.

**Tip:** Always consider the height of your workspace. Ensure your hoist can easily operate within the given dimensions.

Safety features are vital. Look for units equipped with overload protection. This prevents load exceeding limits, reducing the risk of accidents. A high-quality brake mechanism is also essential. It should secure loads firmly in place.

Reflect on the maintenance needs as well. A hoist with easy access for lubrication can prolong its lifespan. Regular checks are necessary to keep the hoist in optimal condition.

**Tip:** Don't ignore the user manual. It holds valuable maintenance tips and safety information. Always prioritize regular inspections on your equipment for peace of mind.

When selecting a manual chain hoist, load capacity and safety ratings play crucial roles. The best models often handle loads from 0.5 tons to 5 tons. According to industry reports, hoists with higher load capacities, like those rated over 3 tons, are more reliable for heavy applications. Safety ratings, measured through rigorous testing, ensure that these hoists can withstand stress without failure.

Tip: Always check the manufacturer's safety certifications. This ensures that the hoist meets industry standards. Some reports suggest that a hoist's design can impact safety. Consider hoists with features like overload protection and improved chain material. These aspects can enhance durability and safety during operations.

However, it’s essential to recognize that even the best hoists can fail without proper maintenance. Regular inspections are vital. Inspect the chain for wear and corrosion. Small issues can lead to significant problems. Choosing a hoist requires careful consideration of its specifications and your specific needs. Ultimately, the right choice can enhance productivity and maintain safety on your job site.

| Model | Load Capacity (tons) | Lift Height (ft) | Weight (lbs) | Safety Rating |

|---|---|---|---|---|

| Model A | 1.0 | 10 | 15 | 4.8/5 |

| Model B | 2.0 | 15 | 20 | 4.6/5 |

| Model C | 3.0 | 12 | 25 | 4.9/5 |

| Model D | 1.5 | 8 | 12 | 4.7/5 |

| Model E | 2.5 | 14 | 22 | 4.5/5 |

| Model F | 3.5 | 16 | 30 | 4.9/5 |

| Model G | 4.0 | 20 | 35 | 4.8/5 |

| Model H | 5.0 | 18 | 40 | 4.7/5 |

| Model I | 2.0 | 13 | 18 | 4.6/5 |

| Model J | 3.0 | 15 | 27 | 4.9/5 |

When evaluating manual chain hoists, understanding the balance between price and performance is crucial. These tools may range widely in cost, but a higher price doesn’t always guarantee better performance. For instance, some budget models can lift heavy loads effectively, yet may lack durability. Smaller, less expensive hoists could be perfect for light tasks, while heavy-duty models are essential for industrial jobs.

Tips for selecting the right hoist: Consider the weight capacity you truly need. Overestimating your requirements can lead to unnecessary expenses. Also, take into account the lifting height. Sometimes a cheaper hoist will fall short on this metric.

Don't forget to compare the gear ratios. A hoist with a higher gear ratio will require less effort to lift heavy items. However, this often comes with a trade-off in speed. Finding that sweet spot is challenging.

Always read user reviews for real-world insights. Sometimes, numbers on paper don't tell the full story. Trust your instincts about what feels right for your tasks. Balancing price with performance metrics can lead to unexpected choices.

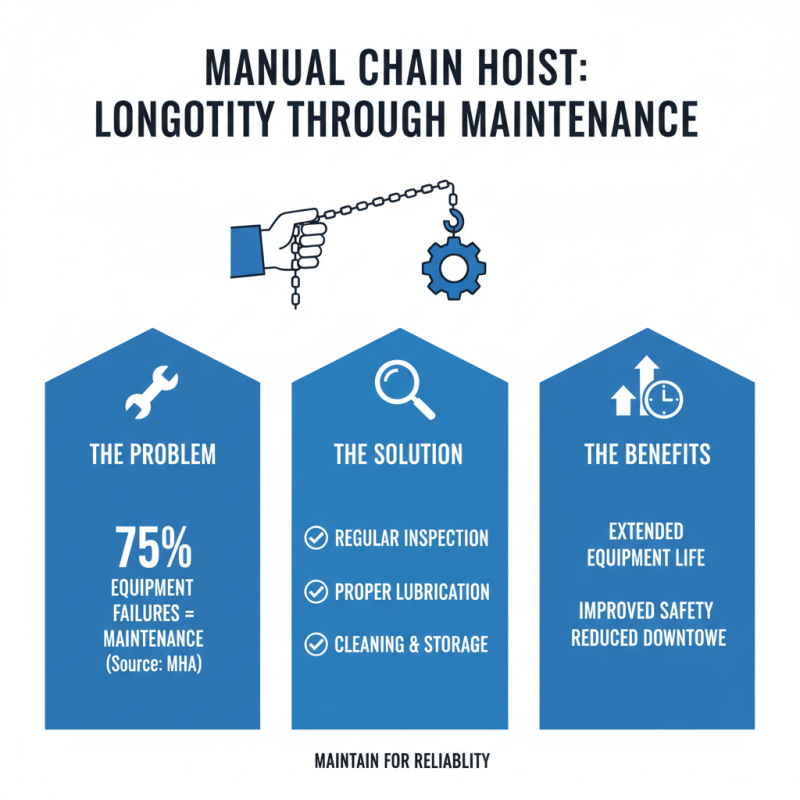

Manual chain hoists are essential tools in various industries. To ensure their longevity, proper maintenance is crucial. A study by the Material Handling Industry Association states that 75% of equipment failures relate to inadequate maintenance practices. Regular inspection and proper care can significantly extend the life of these hoists.

One tip is to clean the chain regularly. Dirt and debris can cause wear and tear, reducing efficiency. Use a soft cloth and appropriate cleaning agents. After cleaning, consider applying a light lubricant to prevent rust.

It’s also vital to check for any signs of wear. Inspect hooks, chains, and gear mechanisms. A worn chain can snap under stress, leading to accidents. Take note: even small cracks can be a signal of deeper issues. If any part seems compromised, replacing it promptly is better than risking failure later. Regular lubrication keeps components running smoothly. However, over-lubrication can attract dirt, so balance is key.

Storing your hoist correctly is just as important. It should be kept in a dry environment to avoid corrosion. If possible, hang it up rather than placing it directly on the floor. This minimizes damage from impacts or moisture. Making these adjustments can help ensure your manual chain hoist remains operational for years.