Inquiry

Form loading...

-

E-mail

-

Whatsapp

The demand for efficient elevation solutions continues to rise. Among these, the Movable Hydraulic Lift stands out due to its versatility and operational efficiency. According to a recent industry report from the Material Handling Institute, the market for hydraulic lifts is projected to grow by 7% annually through 2026. This growth reflects the increasing reliance on advanced lifting solutions across various sectors, from construction to warehousing.

Expert John Mitchell, a leading authority in lifting equipment, stated, “The future of material handling hinges on innovation in hydraulic systems.” His insight underscores the importance of selecting the right Movable Hydraulic Lift to enhance productivity. These lifts are designed to meet various operational needs, but choosing the wrong model can lead to inefficiencies.

While the advancements in technology present many options, they also complicate decision-making. Enthusiasts should consider specifics like load capacity and mobility features. Awareness of these factors can prevent costly mistakes. As industries evolve, the challenge remains to select the ideal lift that aligns with both current needs and future demands.

When selecting a movable hydraulic lift, consider key features that can enhance efficiency. Load capacity is vital. Many hydraulic lifts have a range between 500 to 10,000 pounds. Assess the specific weight requirements of your tasks to ensure safety. Data from the Material Handling Industry found that improper capacity usage leads to 30% of workplace accidents. Understanding lifting speed is essential. A typical hydraulic lift operates at a speed of 0.5 to 1.5 inches per second. If a lift is too slow, productivity can suffer significantly.

Stability is another critical factor. A lift should have a stable base for safe operation. According to industry reports, 20% of lift-related injuries stem from unstable lifts. Features like non-slip surfaces and safety cages can mitigate these risks. Consider portability as well. A hydraulic lift should be easy to maneuver. Some models come with swivel wheels for better navigation. However, heavy lifts can be cumbersome, making their portability questionable.

Investing time to research and reflect on these features is essential. Each lift has unique specifications and options. Take the time to evaluate what best suits your needs. The right choice not only increases efficiency but also enhances safety.

In 2026, the market for movable hydraulic lifts has expanded significantly. These lifts facilitate efficient elevation solutions for various applications. Choosing the right unit can be challenging. A comparative analysis reveals key differences among the top options available this year.

When examining features, consider weight capacity and height range. Many lifts boast impressive lifting abilities. However, not all models offer stability at maximum height. Testing the lift under load is crucial. Remember, experience can vary depending on user needs. For some, portability outweighs lifting power. For others, height is non-negotiable.

Tips: Always check user reviews. They provide real-world insights. Additionally, think about maintenance costs. Some models require frequent upkeep. This can add to overall expenses. Ensure you know how often maintenance is needed.

Safety features are another critical aspect. Look for automatic shut-off systems. They can prevent accidents during operation. Always prioritize your safety and that of your team. The perfect lift may not exist, but understanding your requirements will bring you closer to the right choice.

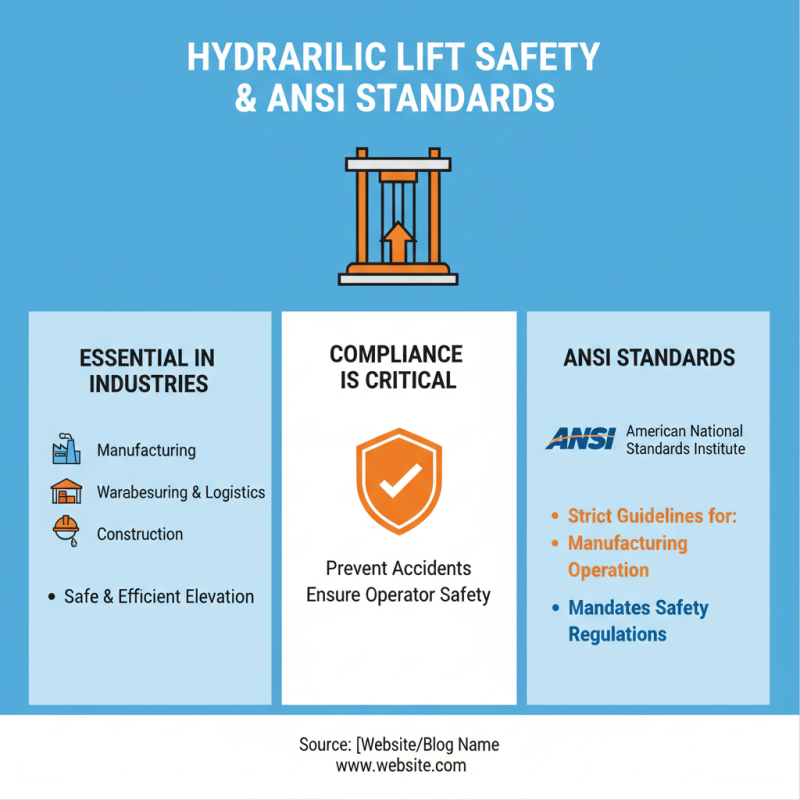

Hydraulic lifts are essential in various industries, ensuring safe and efficient elevation solutions. Compliance with safety standards is critical. The American National Standards Institute (ANSI) mandates strict guidelines for hydraulic lift manufacturing and operation. These regulations help prevent accidents and ensure operator safety.

Recent data reveals a concerning trend. Approximately 25% of all lift-related accidents arise from mechanical failures. Regular maintenance and adherence to safety protocols can mitigate these risks. Operators often overlook the importance of routine checks. This negligence can lead to serious accidents, highlighting a significant flaw in workplace safety culture.

The Occupational Safety and Health Administration (OSHA) emphasizes proper training in hydraulic lift use. However, many employees do not receive adequate instruction. This knowledge gap can result in improper usage, ultimately compromising safety. Investing in proper training programs should be a priority, yet many companies fail to implement them effectively. Each incident serves as a reminder of the ongoing need for vigilance in adhering to safety standards.

Movable hydraulic lifts are gaining traction in various sectors. Their ability to enhance efficiency is clear. However, it’s crucial to consider their cost-efficiency. A recent market analysis reveals significant trends in 2026.

Initial investments can be high. Yet, their long-term benefits are compelling. Reduced manual labor and increased productivity can offset costs. Many businesses find that the savings from improved efficiency outweigh the purchase price. Yet, not all lifts are suitable for every situation. It’s vital to evaluate specific needs before making a decision.

Maintenance costs should also be factored in. Regular upkeep can prevent major issues down the line. Neglected lifts can lead to higher expenses and safety risks. Understanding these constraints is essential for making an informed choice. Every investment requires careful thought. Balancing initial costs and long-term gains can be tricky, but it’s necessary for success.

| Model | Load Capacity (lbs) | Max Height (ft) | Weight (lbs) | Price ($) | Energy Efficiency Rating |

|---|---|---|---|---|---|

| Model A | 1500 | 20 | 300 | 4500 | A+ |

| Model B | 2000 | 22 | 350 | 5200 | A |

| Model C | 2500 | 25 | 400 | 5800 | B+ |

| Model D | 3000 | 30 | 500 | 6500 | B |

Hydraulic lift technology is advancing rapidly, focusing on efficiency and safety. Recent reports indicate that the global hydraulic lift market is expected to reach $35 billion by 2026, reflecting a growing demand for innovative solutions. This trend is largely driven by the construction and manufacturing sectors, where the need for reliable elevation solutions is paramount.

New designs incorporate lighter materials. This innovation can reduce energy consumption by approximately 20%. Improved hydraulic systems also enhance lifting capabilities. Many modern lifts can now move loads upwards of 10 tons with incredible precision. However, there are challenges. Some systems still suffer from energy inefficiencies, leading to unnecessary costs. Regular maintenance is crucial to address these issues, ensuring optimal performance.

Sustainability is another focal point. Eco-friendly hydraulic oils are gaining traction. Reports show that using these oils can decrease environmental impact significantly. Nevertheless, some companies struggle to transition to greener alternatives. The balance between performance and eco-friendliness remains a pressing concern. The industry is still learning and adapting. Future developments aim to optimize efficiency and reduce the carbon footprint.