Inquiry

Form loading...

-

E-mail

-

Whatsapp

In industrial and construction environments, the demand for efficient lifting solutions has led to the increased adoption of motorized hoists. According to a recent report by Market Research Future, the global material handling equipment market is projected to grow at a compound annual growth rate (CAGR) of 4.5% during the next decade. Within this market, motorized hoists are becoming increasingly vital due to their ability to facilitate safe and efficient lifting operations. These devices not only improve productivity but also enhance safety, which is a paramount concern in various sectors.

When selecting the right motorized hoist, it is essential to consider factors such as load capacity, lift height, and power source. The Occupational Safety and Health Administration (OSHA) has emphasized that choosing the appropriate lifting equipment can significantly reduce workplace accidents. This highlights the importance of making informed decisions when it comes to equipment selection. As businesses continue to optimize their operations, understanding the specific needs of their lifting tasks and the different types of motorized hoists available will be crucial to maximizing efficiency and safety. This guide will provide insights into how to choose the right motorized hoist tailored to your lifting requirements.

When selecting a motorized hoist, it's essential to understand the various types available and their specific applications. Motorized hoists are typically categorized into electric, pneumatic, and hydraulic types. Electric hoists are popular for their efficiency and ease of use, making them ideal for warehouse operations and manufacturing environments. Pneumatic hoists, powered by compressed air, are well-suited for settings where electrical sources are limited, such as in hazardous environments. Hydraulic hoists provide strong lifting capabilities and are often used in construction and heavy-duty applications.

Tips for choosing the right hoist include assessing the weight capacity you need. Ensure that the hoist you select can comfortably lift and support your heaviest load. Additionally, consider the height and distance you need to lift items—some hoists are better suited for vertical lifting while others can handle horizontal movement effectively.

Another important aspect is the operating environment. If your application involves high temperatures or exposure to corrosive materials, investing in a hoist that offers superior durability and safety features is crucial. Lastly, always refer to safety guidelines and manufacturer specifications to ensure optimal performance and compliance with regulations.

| Type of Hoist | Load Capacity (lbs) | Lifting Speed (ft/min) | Power Source | Common Applications |

|---|---|---|---|---|

| Electric Chain Hoist | 1,000 - 5,000 | 10 - 20 | Electric | Construction, Warehousing |

| Electric Wire Rope Hoist | 5,000 - 15,000 | 5 - 15 | Electric | Industrial Lifting, Heavy Equipment |

| Pneumatic Hoist | 500 - 3,000 | 20 - 30 | Compressed Air | Automotive, Assembly Lines |

| Battery Powered Hoist | 300 - 1,500 | 15 - 25 | Battery | Construction Sites, Field Work |

| Manual Hoist | 1,000 - 2,000 | N/A | Manual | General Purpose, Maintenance |

When selecting a motorized hoist for your lifting needs, evaluating lifting capacities is crucial for ensuring safety and efficiency. The load limit of the hoist must align with the weight of the items you plan to lift. Underestimating the required capacity can lead to equipment failure or accidents, while overestimating can result in unnecessary costs and reduced operational efficiency. Always consider the maximum weight you will lift and add a safety margin to accommodate any unexpected loads or additional lifting equipment.

Tips for choosing the right load limit include assessing the heaviest item you will regularly lift and factoring in the potential for future use cases. Additionally, consider the type of materials being lifted, as certain materials may require a higher safety factor. It's important to check not only the hoist’s capacity but also the integrity of the lifting attachments to ensure they can handle the load safely.

Another key aspect to keep in mind is the environment in which the hoist will be used. Outdoor conditions, moisture, and potential obstructions can affect both the lifting process and the longevity of the hoist. Choosing a model suited for your specific work environment can enhance performance and safety.

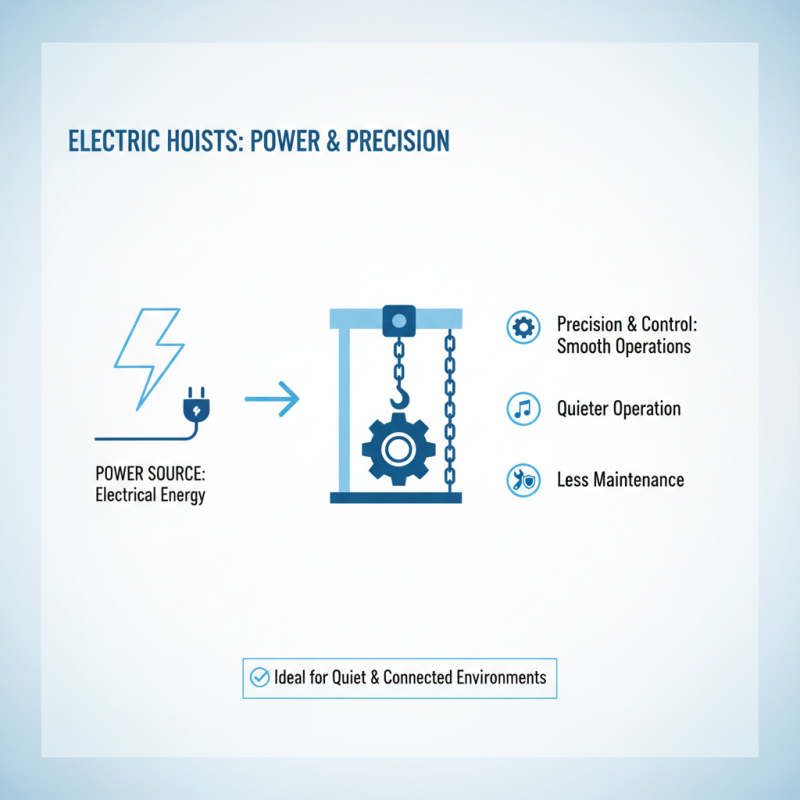

When it comes to selecting a motorized hoist, one of the primary considerations is the power source, with electric and pneumatic options being the most common. Electric hoists utilize electrical energy to lift loads, making them suitable for environments where electrical connections are readily available. They offer precision and control, allowing for smooth lifting operations and quick adjustments. Electric hoists are generally quieter and require less maintenance compared to their pneumatic counterparts, making them a favorable choice in quieter work environments.

On the other hand, pneumatic hoists operate using compressed air, making them ideal for applications in hazardous or explosive settings where sparks from electric motors could pose a risk. They are also highly durable and capable of operating in challenging conditions, such as extreme temperatures or environments with moisture. Pneumatic hoists tend to provide a higher lifting speed, which can enhance productivity in fast-paced operations. However, they require access to a compressed air source, which might limit their use in certain situations. Ultimately, the decision between an electric and pneumatic hoist should be based on the specific requirements of the lifting task, including the operational environment, load characteristics, and safety considerations.

When selecting a motorized hoist, one of the critical factors to consider is the control mechanism—wired vs. wireless. Each option comes with its distinct advantages, and understanding these differences is essential for optimizing operational efficiency. A report by the Occupational Safety and Health Administration (OSHA) highlights that nearly 70% of lifting operations can be performed more safely with remote control options, illustrating the significant impact that control mechanisms can have on productivity and safety.

Wired control systems offer reliability, particularly in heavy-duty applications where the environment may pose interference risks to wireless signals. According to a study by the International Journal of Industrial Ergonomics, wired controls minimize latency and enhance precision during operation, making them ideal for complex maneuvering tasks that require steady, consistent lifting. However, these systems can limit operator mobility, potentially creating safety hazards as operators may be forced to position themselves in unsafe locations to control the hoist.

On the other hand, wireless control mechanisms provide unparalleled flexibility, allowing operators to maintain a safe distance from the load being lifted. A survey by the Material Handling Industry indicates that 85% of operators prefer wireless controls due to their convenience and the safety benefits of remote operation. Moreover, advancements in wireless technology have led to significant reductions in signal interference, with the latest models boasting a range of up to 300 feet without loss of signal integrity. This improvement not only enhances the efficiency of lifting tasks but also contributes to operator comfort and safety by minimizing the risk of accidents.

When selecting a motorized hoist for your lifting needs, considering installation and maintenance requirements is crucial for ensuring

optimal performance. Proper installation is the backbone of effective operation. It involves not just securing the hoist

physically, but also ensuring electrical connections are compliant with safety standards. This includes assessing the power

supply, ensuring that the hoist's capacity aligns with the specific demands of the environment, and understanding how it

will interact with existing structures. An installation performed by professionals familiar with safety regulations can

greatly reduce the risk of malfunctions.

Maintenance is equally important for prolonging the life of your motorized hoist.

Regular inspections can identify wear and tear before they lead to significant issues.

Key maintenance tasks include checking the electrical components, lubricating moving parts,

and ensuring that all safety features are functioning correctly.

By developing a proactive maintenance schedule, operators can optimize the hoist's performance, minimize

downtime, and ensure a safe working environment. Emphasizing these installation and maintenance

aspects not only enhances the efficiency of the hoist but also protects the investment over time.