Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the fast-paced world of construction and maintenance, ensuring safety and efficiency is of utmost importance. One of the most widely utilized tools in this sector is the Electric Hoist Scaffold, a system designed to elevate workers and materials to significant heights. As safety becomes a top priority, understanding how to operate this equipment effectively can dramatically reduce the risks associated with aerial work. Industry expert John Smith, a seasoned safety consultant with over 20 years of experience in scaffold usage, emphasizes, "Proper training and adherence to safety protocols are essential for maximizing the benefits of Electric Hoist Scaffolds while minimizing hazards."

The importance of correct usage cannot be overstated. The Electric Hoist Scaffold not only enhances productivity but also plays a critical role in safeguarding workers from potential accidents. With advancements in technology, modern Electric Hoist Scaffolds come equipped with innovative features that can improve safety significantly. However, without a clear understanding of operational procedures and precautions, these benefits can quickly turn into risks. Through a careful examination of essential tips for using Electric Hoist Scaffolds, we aim to equip operators and construction professionals with the knowledge they need to foster a safe working environment while effectively utilizing this indispensable tool.

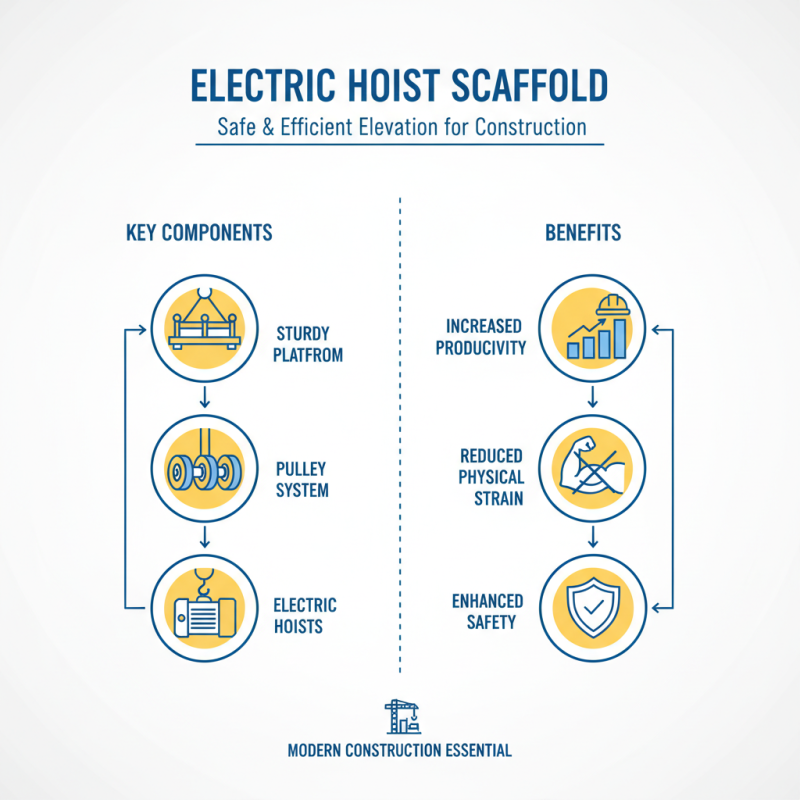

Electric hoist scaffolds are an essential tool in modern construction, providing a safe and efficient means to elevate workers and materials. Understanding the basic components of these scaffolds is crucial for anyone involved in construction projects. They typically consist of a sturdy platform supported by a system of pulleys and electric hoists, designed to lift and lower heavy loads with ease. This design not only enhances productivity but also minimizes the physical strain on workers, allowing them to focus more on their tasks rather than on heavy lifting.

Safety features are paramount in the operation of electric hoist scaffolds. Operators must be trained to understand load limits and proper usage protocols to prevent accidents. Regular inspections and maintenance of the hoist system are vital to ensure that all components function correctly. Additionally, clear communication between workers on the scaffold and those below contributes to a safer working environment. By adhering to these fundamental principles, the use of electric hoist scaffolds can significantly improve both efficiency and safety on the construction site.

When utilizing electric hoist scaffolds, it is paramount to adhere to key safety regulations to ensure both effective operation and the safety of all personnel involved. Firstly, operators must be familiar with the manufacturer's specifications and guidelines, which detail the limits and capabilities of the scaffold. Failing to comply may not only compromise safety but also lead to costly damages.

One essential tip is to conduct thorough inspections before each use. Check for any signs of wear or damage in the hoist, shackles, and scaffolding components. This step helps prevent accidents caused by equipment failure. Additionally, operators should receive proper training on handling electric hoist scaffolds, covering both operational techniques and emergency procedures. Knowledge of weight limits and load distribution is essential, as overloading can significantly increase the risk of collapse.

Moreover, maintaining clear communication among team members is crucial when operating electric hoist scaffolds. Establishing clear signals or using two-way radios can ensure everyone is aware of movements and potential hazards. By following these guidelines, workers can create a safer work environment, minimizing risks associated with electric hoist scaffold operations.

When using electric hoist scaffolds, proper inspection protocols are crucial for ensuring safety and operational effectiveness. Before each use, it is essential to conduct a thorough visual inspection of all components of the scaffold system. This includes checking the integrity of the hoist mechanisms, the stability of the base, and the condition of the scaffolding platform. Any signs of wear, rust, or damage should be identified and addressed immediately to prevent potential failures during operation.

In addition to visual inspections, regular maintenance checks should be scheduled to ensure that all parts are functioning properly. This involves testing the electric hoist's lifting capacity and ensuring that safety features, such as emergency stop buttons and limit switches, are operational. Keeping a detailed log of these inspections and maintenance activities not only helps in tracking the scaffold's condition over time but also demonstrates compliance with safety standards. By rigorously adhering to these inspection protocols, users can significantly reduce the risks associated with electric hoist scaffolds.

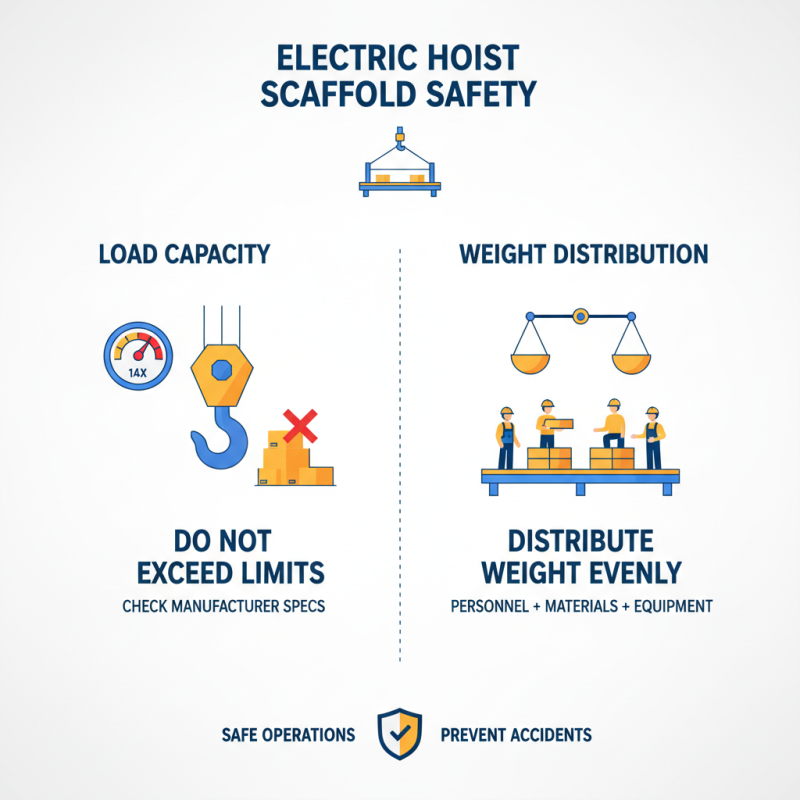

When using electric hoist scaffolds, understanding load capacity and proper weight distribution is vital for ensuring safe operations. Each scaffold has a designated load limit, which should not be exceeded under any circumstances. Always check the manufacturer's specifications before beginning a project to ensure that the total weight of materials, equipment, and workers does not surpass this limit. This practice not only protects the integrity of the scaffold but also minimizes the risk of accidents and injuries.

Additionally, effective weight distribution plays a crucial role in maintaining the stability of the scaffold during use. Distributing the load evenly across the scaffold can prevent tipping and ensure that all parts are engaged properly. For instance, when placing materials, heavier items should be positioned closer to the center of the scaffold while lighter items can be placed further away. It's also crucial to regularly inspect the setup for any signs of imbalance or wear. By prioritizing weight distribution and adhering to load capacity guidelines, operators can enhance the safety and efficiency of their work environment.

Training is a crucial component in ensuring the safe and effective use of electric hoist scaffolds. According to the Occupational Safety and Health Administration (OSHA), inadequate training is a leading cause of workplace accidents involving scaffolding systems. Operators should undergo comprehensive training programs that not only cover the operational aspects of the electric hoist scaffolds but also emphasize safety protocols and risk management strategies. Employees trained in the safe use of scaffolding are 70% less likely to be involved in workplace accidents, highlighting the importance of proper education and oversight.

Moreover, effective training should be tailored to the specific equipment and work environment. Programs should include hands-on training sessions and theoretical knowledge that covers load capacity, maintenance requirements, and emergency procedures. Statistics from the National Institute for Occupational Safety and Health (NIOSH) indicate that organizations that invest in worker training experience a significant reduction in accident rates and injuries. In fact, a well-structured training program can result in up to a 50% decrease in scaffold-related incidents, ultimately protecting workers and improving overall productivity on job sites.

| Tip Number | Safety Tip | Description | Training Requirement |

|---|---|---|---|

| 1 | Conduct Pre-Use Inspections | Ensure the hoist and scaffold are in good working condition before use. | Operators must complete daily inspection training. |

| 2 | Use in Suitable Weather Conditions | Avoid using at high winds or during storms. | Operators must be trained on weather-related hazards. |

| 3 | Adhere to Load Limits | Never exceed the maximum rated load capacity of the scaffold. | Operators must understand load capacity training. |

| 4 | Proper Use of Safety Harnesses | Ensure operators use safety harnesses when working at heights. | Training on harness use and fall protection is required. |

| 5 | Maintain Clear Communication | Establish signals or methods for communicating with ground crew. | Training on communication protocols is essential. |

| 6 | Store Materials Safely | Avoid placing materials near the edge of scaffolds. | Training on material handling is required. |

| 7 | Ensure Clear Exit Routes | Keep pathways and access points clear at all times. | Operators should understand egress training. |

| 8 | Regular Equipment Maintenance | Schedule routine maintenance checks to ensure functionality. | Operators should be trained on maintenance protocols. |

| 9 | Stay Alert and Avoid Distractions | Maintain focus on the task to prevent accidents. | Operators should receive training on workplace concentration. |

| 10 | Know Emergency Procedures | Be familiar with evacuation plans and emergency contacts. | Emergency procedures training must be conducted. |