Inquiry

Form loading...

-

E-mail

-

Whatsapp

In today's fast-paced business environment, efficiency and safety are paramount, especially when it comes to the transportation of heavy goods. A Hydraulic Cargo Lift has emerged as a vital solution for a wide range of industries, from warehouses and distribution centers to manufacturing plants. Industry expert John Smith, an engineer with over 15 years of experience in material handling solutions, emphasizes, "The Hydraulic Cargo Lift not only streamlines the movement of goods but also enhances workplace safety by reducing the risk of injury associated with manual lifting."

Understanding how a Hydraulic Cargo Lift works is essential for businesses looking to optimize their operations. This innovative lift system employs hydraulic mechanisms to elevate and lower cargo seamlessly, allowing for smooth transitions between different levels of a facility. By utilizing this technology, companies can increase productivity while minimizing downtime and labor costs. Moreover, the adaptability of Hydraulic Cargo Lifts makes them suitable for various applications, ensuring that they can meet the specific needs of any operational setting.

As businesses continue to seek ways to maximize efficiency and maintain safety standards, the role of Hydraulic Cargo Lifts will only become more significant. By investing in this essential equipment, companies position themselves for success in an increasingly competitive marketplace, paving the way for improved logistics and a more effective workflow.

A hydraulic cargo lift is a mechanical device designed to transport heavy goods between different levels of a building or industrial facility. At its core, a hydraulic lift utilizes the principles of hydraulics, which involves the transmission of force through fluid in a closed system. This system allows for the lifting and lowering of loads with ease, providing a practical solution for warehouses, factories, and retail spaces where efficient movement of goods is crucial.

The purpose of a hydraulic cargo lift goes beyond mere transportation; it enhances operational efficiency and safety. By eliminating the need for manual lifting of heavy items, businesses can reduce the risk of workplace injuries and improve workflow. Hydraulic cargo lifts are often customizable, with varying sizes and weight capacities to meet specific needs, making them an essential asset for industries that require regular movement of heavy materials. Their versatility and reliability make them an ideal choice for businesses looking to streamline their logistics and maintain productivity.

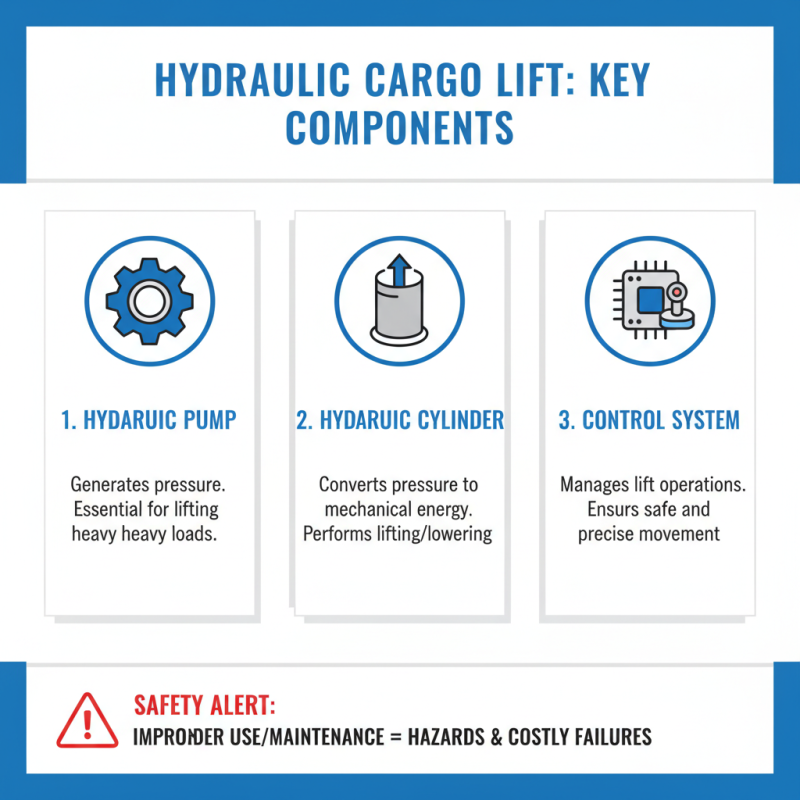

Hydraulic cargo lifts are essential pieces of equipment that facilitate the movement of goods between different levels in warehouses, distribution centers, and manufacturing plants. Understanding the key components of these lifts is crucial for businesses aiming to enhance operational efficiency. The primary elements include the hydraulic pump, hydraulic cylinder, and control system. The hydraulic pump generates the necessary pressure to lift heavy loads, while the hydraulic cylinder performs the actual lifting and lowering by converting that pressure into mechanical energy. According to the Industrial Truck Association, improper use or maintenance of these components can lead to safety hazards and equipment failure, which can disrupt operations and incur significant costs.

Another vital component is the control system, which ensures precise handling of loads. This system monitors and regulates the lift’s operations, providing operators with crucial feedback on load weight, position, and safety alerts. The American Society of Mechanical Engineers (ASME) has established guidelines that highlight the importance of regular inspections and maintenance of these systems to prevent malfunctions. Industry reports suggest that businesses with well-maintained hydraulic lifts can increase their productivity by up to 30%, highlighting the importance of understanding and optimizing the machinery involved in hydraulic cargo lifts.

Hydraulic cargo lifts operate based on the principles of fluid mechanics, which involve the transmission of force through incompressible liquids. At the core of their functionality is Pascal's principle, which states that when pressure is applied to a confined fluid, it is transmitted equally in all directions. This principle underpins the operation of hydraulic systems, allowing a small force applied at one point to result in a much larger force at another point. In the context of a hydraulic cargo lift, this translates to the lifting and moving of heavy loads with minimal manual effort, enhancing efficiency and safety in various commercial settings.

The hydraulic lift system comprises three main components: the pump, cylinder, and fluid. The pump generates pressure by moving hydraulic fluid, typically oil, from the reservoir into the cylinder. As the fluid fills the cylinder, it pushes against a piston, which in turn lifts the attached cargo. The design of hydraulic lifts allows for smooth and controlled vertical movement, making them essential in warehouses, factories, and construction sites where heavy materials need to be transported between different levels. The seamless operation and versatility of hydraulic lifts make them an indispensable tool for any business that requires reliable material handling solutions.

Hydraulic cargo lifts are increasingly becoming essential in various industrial settings due to their numerous advantages. One of the primary benefits is their ability to streamline the movement of goods between different levels of a facility, thereby improving operational efficiency. According to a report by the Industrial Truck Association, the implementation of hydraulic lifting systems can enhance productivity by up to 30%, enabling businesses to handle more cargo with less manual effort. This becomes particularly valuable in industries such as manufacturing, warehousing, and logistics, where time-saving solutions can significantly impact profitability.

Furthermore, hydraulic cargo lifts contribute to workplace safety by reducing the risk of injuries associated with manual lifting. A study conducted by the Occupational Safety and Health Administration (OSHA) indicates that material handling injuries account for over 30% of workplace injuries in industrial environments. By utilizing hydraulic lifts, companies can minimize these risks, fostering a safer work environment while complying with safety regulations. In addition to injury reduction, this technology often requires less space compared to traditional elevators, allowing for more efficient use of floor plans and resources.

Hydraulic cargo lifts have become indispensable in various industries due to their ability to streamline the movement of heavy goods across different levels of a facility. In the logistics sector, for instance, data from the Industrial Truck Association indicates that nearly 70% of all freight transport relies on efficient vertical handling systems. By utilizing hydraulic lifts, warehouses and distribution centers can significantly reduce loading times and improve overall operational efficiency, mitigating labor costs and minimizing the risk of workplace injuries associated with manual lifting.

In manufacturing, hydraulic cargo lifts play a crucial role in maintaining smooth production lines. A report from the Bureau of Labor Statistics highlights that ergonomic solutions, including hydraulic systems, can decrease direct labor costs by up to 15% while improving employee safety and productivity. These lifts allow for the seamless transfer of materials between production stages, facilitating just-in-time manufacturing practices that many companies are adopting to stay competitive in the ever-evolving market. Moreover, industries such as retail are leveraging hydraulic lifts not only for inventory management but also to enhance the customer experience by ensuring quick restocking of products, leading to higher customer satisfaction ratings as indicated by recent consumer experience surveys.