0102030405

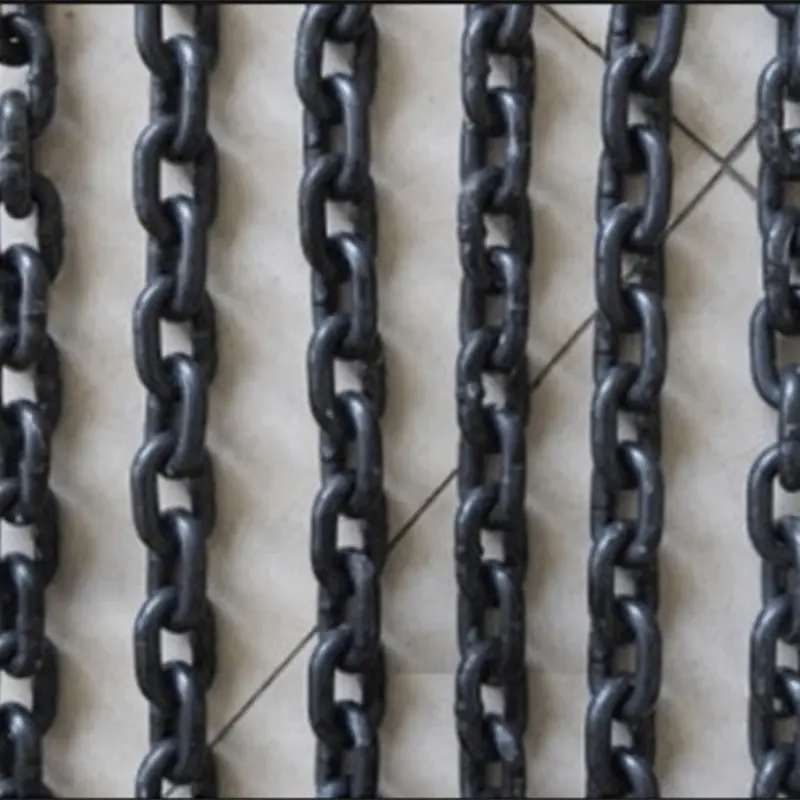

Crane Chain. Crane Manganese Steel Chain

Working Principle

The working principle of the lifting chain is to drive the chain to rotate through an electric motor, causing the hook to move up and down. Specifically, the hook is connected to the motor through a chain. When the motor starts running, the chain begins to rotate, and the hook rises or falls accordingly, thereby achieving the lifting or lowering of goods.

Components and functions of lifting chains

A lifting chain is usually composed of an electric motor, a chain, and a hook. The electric motor provides power, the chain is responsible for transmitting power, and the hook is used for hanging and lifting goods. These components work together to ensure that the lifting chain can efficiently and safely complete the lifting operation.

Scope of Use

The main uses of lifting chains include lifting heavy objects, towing, and bundling. As an accessory for electric hoists, chain hoists, group hoists, etc., lifting chains are commonly used to lift heavy objects. In addition, lifting chains can also be used for traction and bundling, with specific application scenarios as follows:

Purpose of lifting: The lifting chain plays a crucial role in cranes and is an essential lifting device. By adjusting the length of the chain, it is possible to adapt to lifting requirements at different heights, thereby improving work efficiency and expanding the scope of work.

Traction purpose: The lifting chain can be used to pull heavy objects, especially when moving or dragging heavy objects, the lifting chain can provide sufficient tension and stability.

Binding purpose: In some cases, lifting chains can also be used to bind heavy objects, ensuring their stability and safety during transportation or storage.

In addition, the grade and material of the lifting chain have a significant impact on its performance. For example, lifting chains of grades 80 and 100 are refined through complex processes such as polishing, blackening, dipping, electroplating, and spraying and have high strength and corrosion resistance, making them suitable for various working environments.

Product Attributes

Product name: Crane chain

Texture of material: 20Mh2

Scope of application: Crane rigging.

Surface treatment: Rolling light.

Manganese steel lifting chain.

Carefully select materials.

Time and effort saving.

Manganese steel chain.

High temperature quenching.

The surface has undergone multiple heat treatments such as quenching and tempering.

Using G80 manganese steel raw material.

Carefully selecting materials.

Less prone to wear and tears with higher load-bearing capacity.

Product specifications

Applicable: Metallurgical, construction building materials.

Product features: Smooth surface, stable structure, diverse specifications.

Applicable scenarios: metallurgical building materials/port terminals/factory operations/construction projects, etc.

Product Details

Surface treatment

Smooth welding joint, various specifications after quenching treatment, long service life.

Welding technology

Adopting full welding, complicated process flow, and small size error.

Quality assurance

Forged with manganese steel material, it has good toughness, low ductility, and is not easily deformed under stress.

According to customer request

Abundant inventory, diverse specifications, widely used standard materials, supporting customized matching.