0102030405

Crane Trolley

Product Attributes

Scope of application: Steel wire rope pulley car

Weight: 1Kg

Material of pulley: cast steel

Working Principle

The working principle of the lifting pulley is mainly based on the mechanical principle of the pulley, which achieves the lifting and transportation of heavy objects by changing the magnitude of the tension. The lifting pulley is mainly composed of pulleys, ropes, and fixed devices, among which the pulley is the core component, usually referred to as the pulley group.

The working principle of the lifting pulley can be divided into two main stages: tension transmission and lifting of the lifted object. In the stage of tension transmission, the rope is connected to the pulley system and fixed in a stationary position. When tension is applied to the rope, the pulley system will transmit the tension to the rope, and the rope will bear this tension. A pulley system consists of one or more pulleys, typically cylindrical in shape, that can rotate on it. Each pulley has a groove, and the rope can enter and exit along the path of the groove. When pulling the rope with force, the tension applied to the rope will drive the pulley system to rotate. According to Newton's second law, for a pulley system, the tension transmitted to the rope is equal to the input tension multiplied by the torque ratio of the pulley system. By changing the structure of the pulley system, the proportion of tension transmission can be altered.

During the lifting stage of the suspended object, when the tension is transmitted to the rope through the pulley system, the rope will apply this tension to the heavy object. Heavy objects are subjected to the force of gravity, and the tension of the rope will counteract the force of gravity, thereby keeping the heavy object in a rising, falling, or stationary state. By changing the magnitude of the applied tension, it is possible to achieve control over the lifting and lowering of heavy objects. Usually, people can provide tension by manually pulling ropes, engines, electric motors, or hydraulic systems.

The structure of a lifting pulley includes components such as pulleys, ropes, brackets, and wire ropes. Pulley is the core component of lifting tackle, usually made of sturdy materials that can withstand the weight of heavy objects. The bracket is used to fix the pulley and provide a stable foundation, while the steel wire rope is used to connect the pulley and lift objects. These components work together to ensure that the lifting trolley can efficiently and safely complete the lifting task.

Scope of Use

The lifting pulley is an important lifting tool with the characteristics of simple structure and easy use, widely used in various lifting and transportation operations. The lifting pulley can vertically lift heavy objects through sprockets or drums, with light weight and compact structure, suitable for simple lifting work. The lifting pulley can be used alone or in conjunction with other lifting tools such as winches, winches, masts, etc. to complete lifting operations together. In addition, the lifting pulley can also change the direction of the traction cable between the pulley and the pulley group multiple times, used for lifting or moving heavy objects.

Crane pulleys are widely used in various fields such as construction, factories, mining, agriculture, and electricity, mainly for machine installation and cargo lifting. Its product specifications range from 0.03 tons to 320 tons, with wheel systems ranging from single wheel to pick wheel. The crane has multiple options such as hooks, chain links, lifting rings, and lifting beams, and can be operated manually or manually.

The working principle of lifting pulley is to achieve labor-saving by changing the direction of force and bearing lifting and traction forces. It can also be used as a guiding pulley and a balancing pulley. Due to its convenient use and portability, lifting tackles are widely used in lifting installation operations.

Hoisting Tackle

Strong load-bearing capacity.

Strong power.

Product Analysis

Lightweight and practical wheels.

Good performance and easy maintenance.

High toughness, small size, light weight, easy to carry.

For steel wire ropes, the ropes are not damaged.

Easy to use, versatile, can be manually or maneuvered.

Lifting goods in areas without power supply, powerful function.

Scope of Use

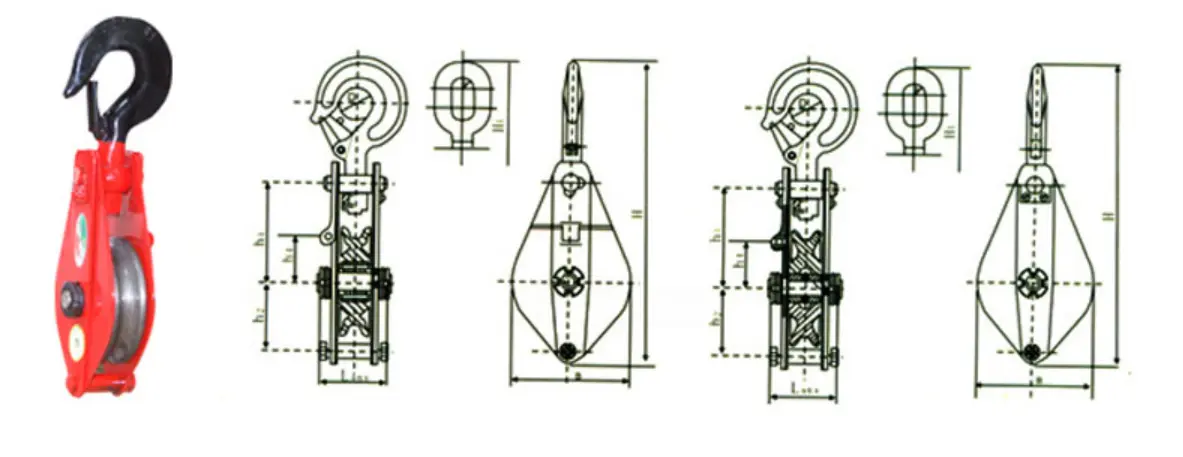

Product Specifications

Technical Parameters

Tonnage |

Wire rope diameter |

Wheel groove diameter |

Weight |

Total length |

|

Suitable |

Maximum |

||||

0.5T |

6.2mm |

7.7mm |

71mm |

1.75Kg |

260mm |

1.0T |

7.7mm |

11mm |

85mm |

3.25Kg |

320mm |

2.0T |

11mm |

14mm |

112mm |

6.0Kg |

390mm |

3.0T |

12.5mm |

15.5mm |

132mm |

10.5Kg |

470mm |

5.0T |

15.5mm |

18.5mm |

160mm |

19Kg |

560mm |

8.0T |

20mm |

23mm |

210mm |

35.2Kg |

765mm |

10T |

23mm |

24.5mm |

240mm |

50.5Kg |

820mm |

16T |

28mm |

31mm |

315mm |

113.5Kg |

1030mm |

20T |

31mm |

35mm |

355mm |

162.2Kg |

1140mm |

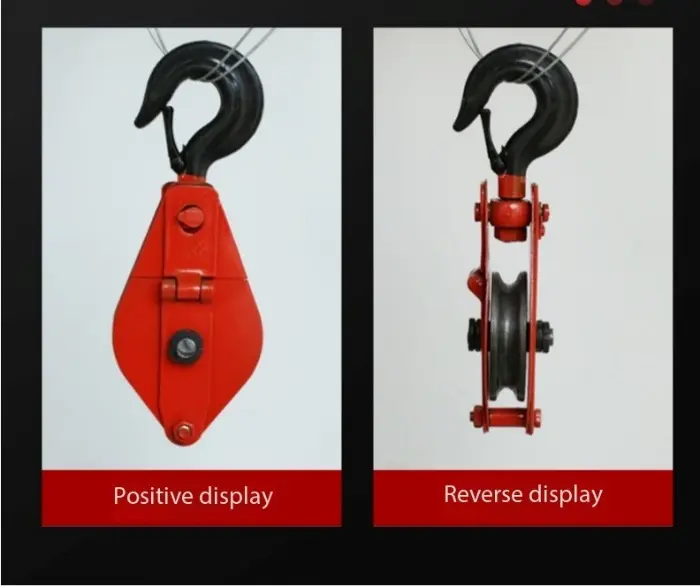

Product Back and Back Display

Front/Back

Multiple options to meet different customer needs.

Bold hook

The pulley is selected with a thickened hook, which has a larger load-bearing capacity and is not easily broken when overloaded. It comes with a safety device.

Open design

The open pulley design is more convenient, concise and suitable for lifting use.

Directional pulley

Made from high-quality alloy and refined through high-temperature quenching, it has high strength, good durability, and a smooth and smooth surface.

Integrated casting

Using an integrated casting process to thicken the material, it is more durable and practical, and can be used for a longer period of time.