0102030405

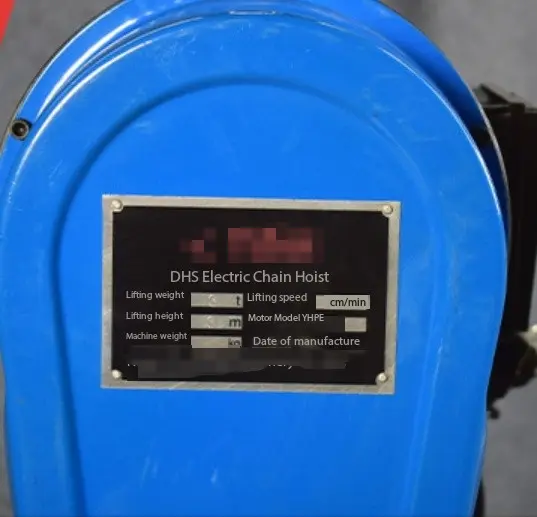

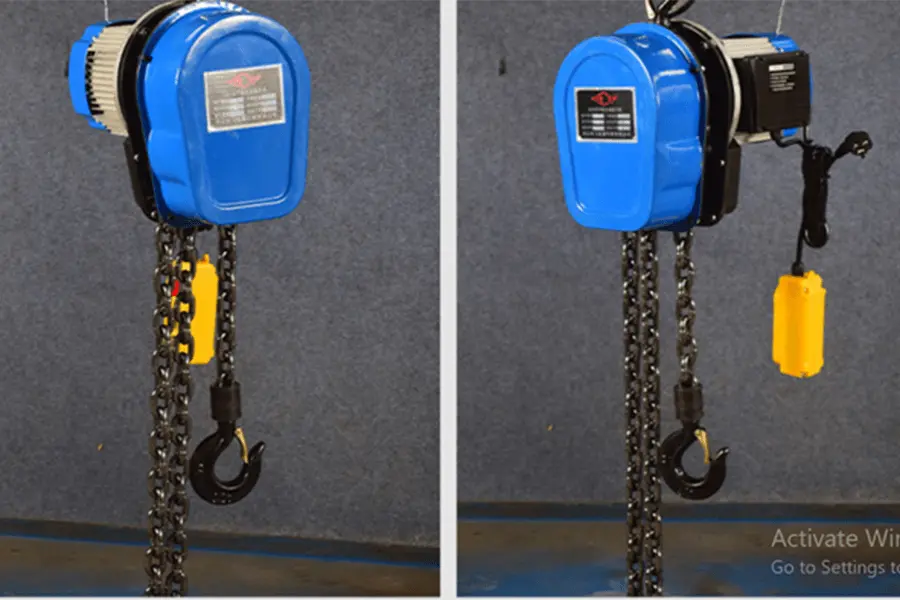

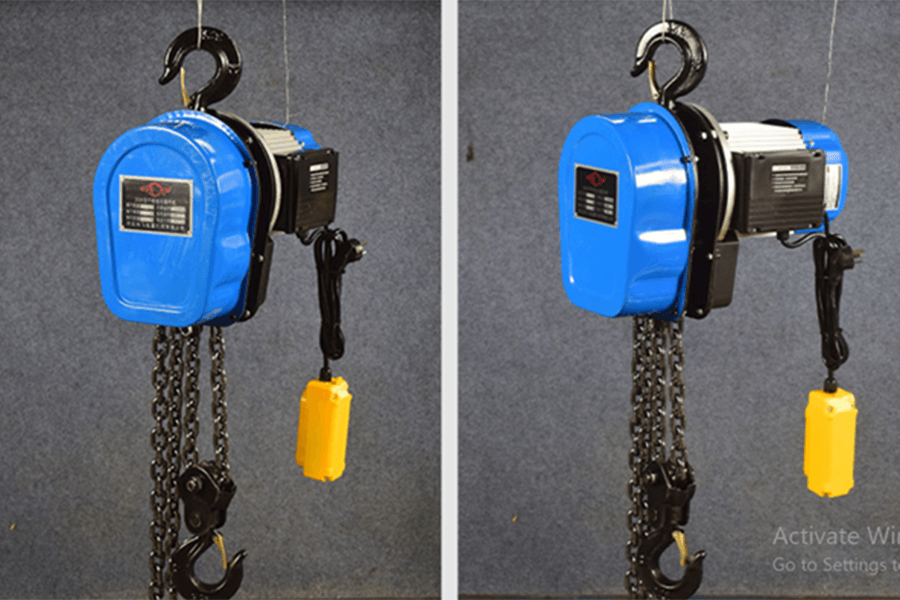

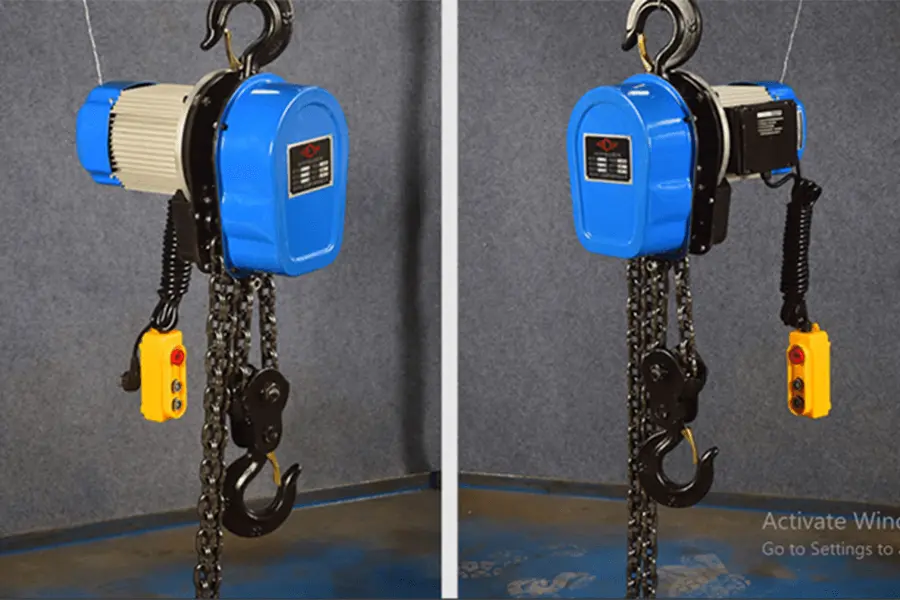

DHS Electric Chain Hoist

Working Principle

-By driving the chain with an electric motor for lifting and lowering movements, material handling is achieved. Its core components include electric motors, reducers, sprockets, chains, and hooks.

Specifically, the workflow of the DHS electric chain hoist is as follows:

Motor drive: After the motor is started, it is reduced by a reducer to drive the sprocket to rotate.

Chain wheel drive: The output shaft of the reducer drives the ring chain wheel to rotate through gear transmission, and the ring chain wheel drives the chain to move during the rotation process.

Lifting hook: The chain is fixed by two lifting hooks, and when the chain wheel drives the chain to move upwards, the lifting hook also lifts upwards.

Control system control: Loop chain electric hoists are usually equipped with an electronic control system, which can control the start and stop of the motor, the speed of the gearbox, the position of the lifting hook, etc.

In addition, the DHS electric chain hoist also has the following characteristics:

-Safe and reliable: adopting advanced control technology and safety protection devices, such as overload protection, fire protection, etc.

-Efficient and energy-saving: With an efficient transmission system and optimized motor design, it has low energy consumption and high efficiency during operation.

-Easy to operate: The operation is simple and convenient, and users only need to use the controller to achieve the lifting and positioning of the device.

-Strong flexibility: suitable for various occasions, such as indoor, outdoor, fixed or mobile installation.

-Low maintenance cost: simple and compact structure, easy to maintain and upkeep.

Scope of Use

The DHS electric chain hoist is suitable for various occasions, including electricity, construction, railways, ports, docks, factories, workshops, warehouses, logistics, coal mines, petrochemicals, automobile manufacturing, mechanical maintenance and other fields. It is mainly used for material lifting, loading and unloading, and handling operations.

Application Area

Power industry: used for lifting and transporting power equipment.

Construction industry: Lifting materials and equipment on construction sites.

Railway and Transportation: Used for the installation and maintenance of railway facilities.

Ports and docks: loading, unloading, and handling of goods at ports and docks.

Warehouse and Logistics: Storage and transportation of goods in warehouses and logistics centers.

Coal mines and petrochemicals: used for equipment hoisting and maintenance in mines and chemical factories.

Automobile manufacturing and mechanical maintenance: Lifting equipment and components in automobile manufacturing plants and mechanical maintenance workshops.

Usage Effect

The DHS electric chain hoist has the following advantages:

Lightweight and convenient: retaining the lightweight characteristics of a chain hoist.

Efficient improvement: The slow lifting speed of the chain hoist has been improved by using a disc brake motor as power and a planetary reducer for deceleration, thereby enhancing work efficiency.

Compact structure: small size, light weight, easy maintenance, and safe use.

Technical parameters

Voltage |

Tonnage standard(T) |

Lenght(m) |

220V |

1 |

3 |

220V |

1 |

6 |

220V |

1 |

9 |

220V |

2 |

3 |

220V |

2 |

6 |

220V |

2 |

9 |

220V |

3 |

3 |

220V |

3 |

6 |

220V |

3 |

9 |

Track model: 80-260

Type: Electric chain hoist

Standard lifting height: 3.0-12m

Increase speed: 2m/min

Chain diameter: 6-10mm

Minimum distance between two hooks: 55-75mm

Rated lifting capacity: 1000-50000Kg

Net weight: 40Kg

Load: 50000Kg

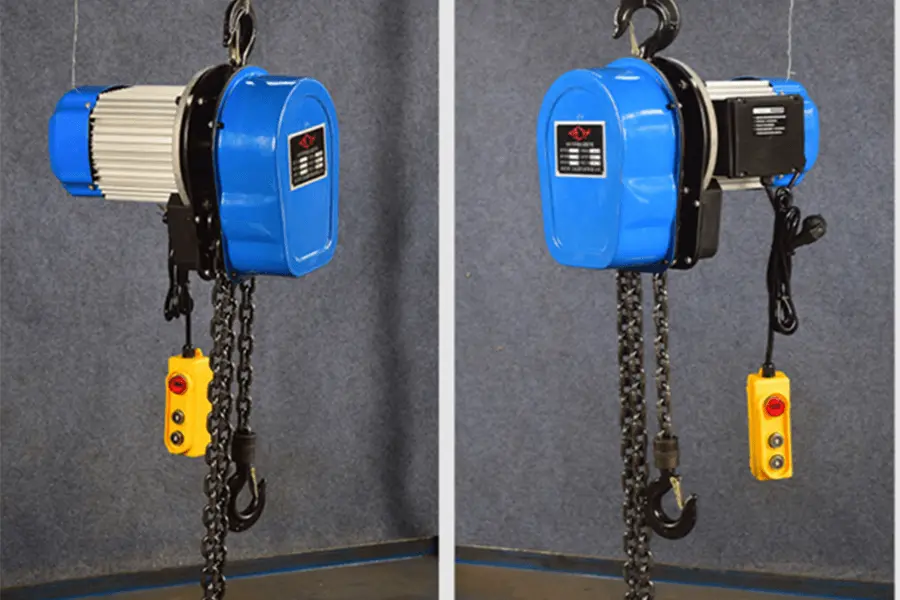

Two different voltages

G80 manganese steel chain

thickened casing for strong impact resistance and protection of internal structure

Quenching hook

The manganese steel hook is equipped with thickened tongue pieces to prevent items from falling off easily

Alloy steel casing

thickened casing with strong impact resistance to protect the internal structure

Portable remote control

lightweight, can be operated with one hand with an engineering plastic casing

1Ton

2Ton

3Ton

5Ton

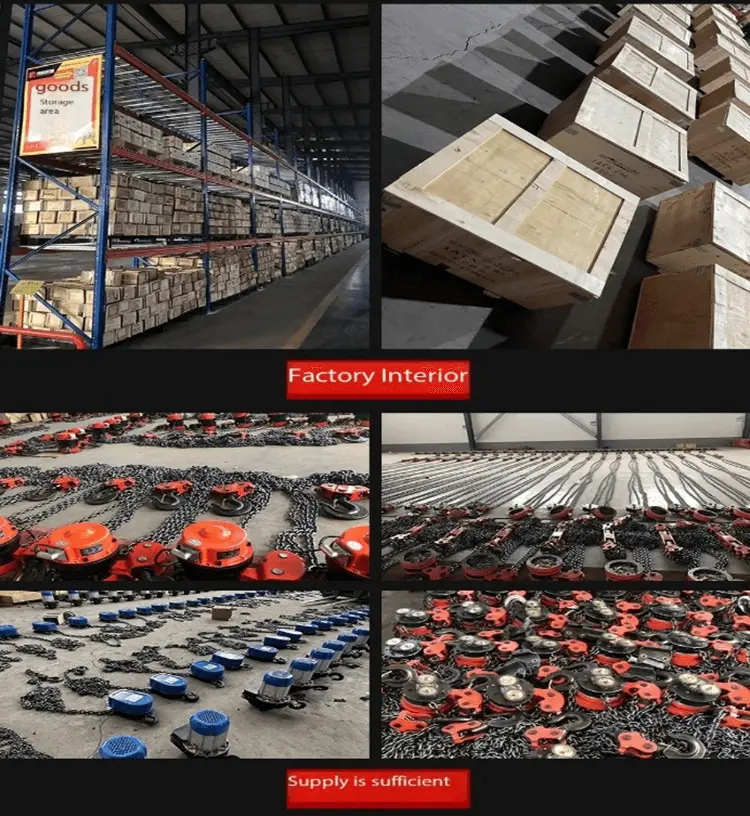

Warehouse Picture