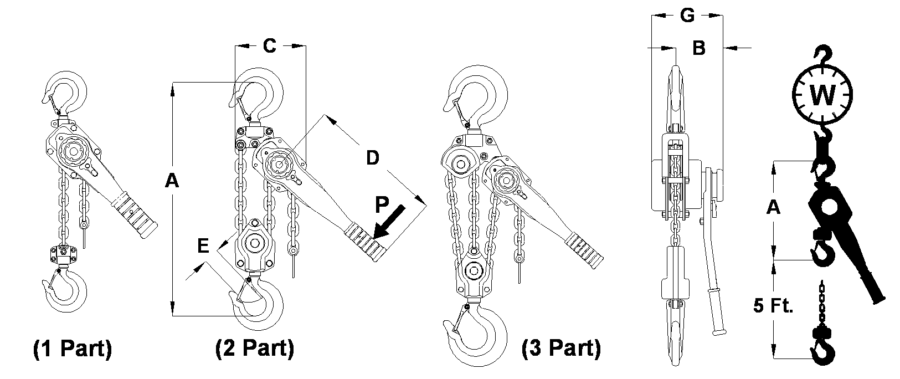

Hand cranked hoist-Hand wire tensioner

Maintenance and safety

Maintaining and ensuring the safety of chain hoists are crucial practices that extend their lifespan and guarantee the safety of the operations in which they’re used. A well-maintained hoist not only performs better but also minimizes the risk of accidents and injuries. Adhering to a strict regimen of maintenance and safety protocols ensures that chain hoists operate efficiently and reliably.

Maintenance tips

-Regular Inspection: Before and after each use, a thorough inspection of the hoist should be conducted. Look for signs of wear, damage, or corrosion on the chain, hooks, and other components. Regular inspection can identify potential issues before they lead to failure.

-Cleaning and lubrication: Keeping the chain hoist clean and well-lubricated is essential for smooth operation. Dirt and debris can cause the chain to grind, leading to premature wear. Proper lubrication reduces friction, preventing wear and extending the life of the hoist.

-Professional servicing: Beyond daily or weekly checks, periodic professional inspections are recommended to assess and service the internal mechanisms that are not accessible for routine checks. This includes the brake system, internal gears, and other critical components that may require adjustment or replacement.

-Documentation: Maintain a log of all inspections, maintenance, and repairs. This documentation can help track the hoist’s condition over time and ensure compliance with any regulatory requirements.

Safety considerations

-Load capacity adherence: Never exceed the hoist’s rated load capacity. Overloading can cause immediate failure or significant wear, leading to future failures. Understanding and respecting the limits of your equipment is fundamental to safe operation.

-Proper operation training: Operators should be thoroughly trained in the correct use of the hoist. This includes understanding how to properly load, lift, and lower loads, as well as being aware of the hoist’s operational limits and safety features.

-Use of personal protective equipment (PPE): Depending on the operation and environment, the use of PPE such as hard hats, gloves, and safety glasses can be crucial in preventing injuries.

-Environment awareness: Ensure that the area around the hoist operation is clear of obstacles and unauthorized personnel. Awareness of the surroundings can prevent accidental collisions and injuries.

-Emergency procedures: Establish and familiarize all operators with emergency stop procedures and what to do in case of a hoist malfunction or load drop.

Best practices

Adopting and enforcing maintenance and safety best practices are integral to the operational integrity of chain hoists. By investing time in routine checks, adhering to operational guidelines, and fostering a culture of safety, organizations can ensure that their hoisting operations are not only efficient but also free of preventable accidents. These practices not only protect the equipment but more importantly, safeguard the operators and other personnel involved in lifting operations.

Comparison with other hoists

Comparing chain hoists to other types of hoists provides valuable insights into selecting the right tool for specific lifting needs. While chain hoists, both manual and electric, are widely used for their simplicity, reliability, and versatility, other hoisting mechanisms like lever hoists and wire rope hoists offer distinct advantages and limitations based on the application.