0102030405

Scaffold Hoists

Working Principle

The working principle of the Scaffold hoists is to use an electric motor to drive the hoist winch to rotate, and lift or lower the load through a cable. Electric hoists are mainly composed of electric motors, winches, ropes, rope control systems, operation panels, and safety protection devices. During use, the electric motor drives the winch to rotate, and the cable passes through the winch winding. The cable control system can control the length and direction of the cable to lift or lower the load. In addition, the electric hoist also has the function of automatically monitoring the load situation to ensure the safety of operation.

The scaffold hoists have advantages of simple structure, easy operation, and high lifting efficiency and is widely used in industrial production, warehousing and logistics, construction engineering, and other fields. It has a beautiful appearance, small size, and light weight. The suspension end adopts a double safety design to ensure the stability of installation. These characteristics make the little electric hoist perform well in various lifting operations that require saving time and effort.

Scope of Use

Scaffold hoists have a wide range of applications, suitable for various scenarios and industries.

Scaffold hoists are mainly used for lifting and moving heavy objects, especially suitable for engineering hoisting, factory hoisting operations, civil engineering, water and electricity piping installation, warehousing and loading, hotel and shopping mall hoisting, etc.

It not only saves time and effort, but also greatly improves work efficiency.

In addition, the scaffold hoists are also suitable for construction sites, civil engineering, general factories, plumbing facilities, coating brackets, warehousing, household use, agriculture, fisheries, storage and other fields, for lifting, hoisting and towing operations.

The technical features and advantages of the scaffold hoists include:

Exquisite technology and superior performance: adopting a 4x safety factor, alloy steel forged hook group, alloy steel heat-treated gear, high strength.

The motor body and gearbox are integrated by aluminum alloy die-casting, with high precision and low noise.

Beautiful appearance: Using car and powder baking paint, the appearance is beautiful.

Easy to operate, suspended installation, simple and fast operation.

Safe and reliable: using Japanese imported steel wire with triple safety technology.

Fast lifting speed: The lifting speed can reach 23 meters per minute, much faster than ordinary wire rope electric hoists.

These characteristics and advantages make the scaffold electric hoist perform well in various application scenarios, becoming an ideal choice for many industries and household users.

Technical Parameters

Model |

Length(m) |

Type |

160Kg |

30 |

Wire controlled model |

180Kg |

30 |

Wire controlled model |

230Kg |

30 |

Wire controlled model |

250Kg |

30 |

Wire controlled model |

300Kg |

30 |

Wire controlled model |

360Kg |

30 |

Wire controlled model |

500Kg |

30 |

Wire controlled model |

160Kg |

30 |

Remote control + wire control |

180Kg |

30 |

Remote control + wire control |

230Kg |

30 |

Remote control + wire control |

250Kg |

30 |

Remote control + wire control |

300Kg |

30 |

Remote control + wire control |

360Kg |

30 |

Remote control + wire control |

500Kg |

30 |

Remote control + wire control |

Type: Wire rope electric hoist

Standard lifting height: 30m

Speed: 5m/min

Chain diameter: 4mm

Minimum distance between two hooks: 300mm

Rated lifting capacity: 500Kg

Scaffold hoists/Little electric hoist copper core motor has strong power and manganese steel chain

Application scope

Production workshops, construction sites, truck use, warehouse workshops.

Powerful and reliable power

Copper core motor/high-strength non burning machine

Compact body with powerful heart power, long service life

Product specifications

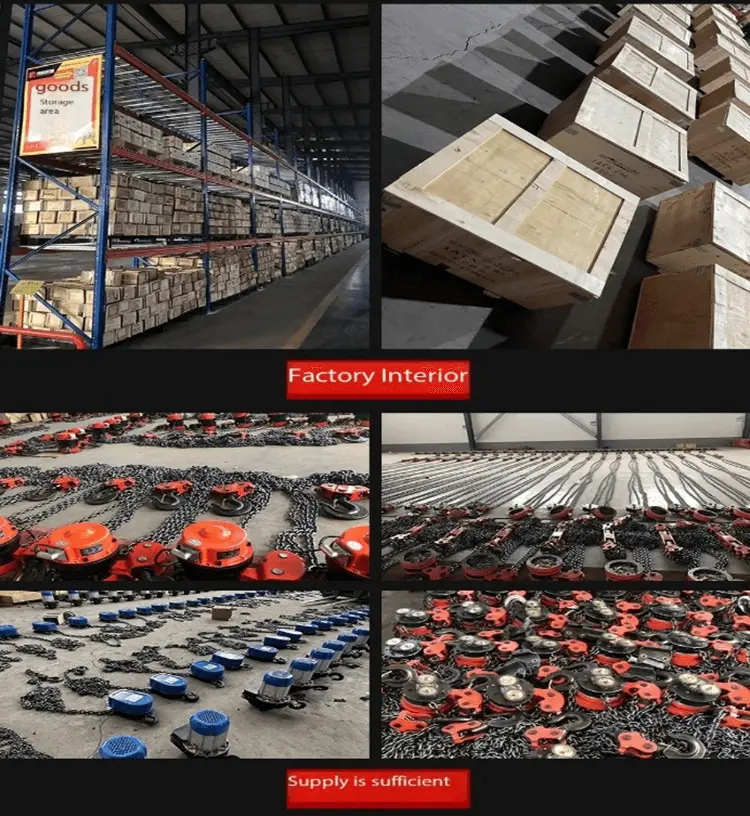

Product packaging: Wooden packaging

Two control options are available

Wired controller/wireless remote control

Multiple options to meet different customer needs

Product details

Anti rotation steel wire rope

High strength alloy galvanized steel wire rope is safe and reliable, with 6 times the tensile strength of the steel wire rope

Double hook design

Ready to use, the hook has multiple protections with insurance cards, making it safer

Special gear steel

Gear lubricating oil is used in conjunction with precision steel 5-wheel rotation for long-lasting stability and high efficiency

Portable remote control

Lightweight, one-handed operation of engineering plastic casing

Warehouse Picture