0102030405

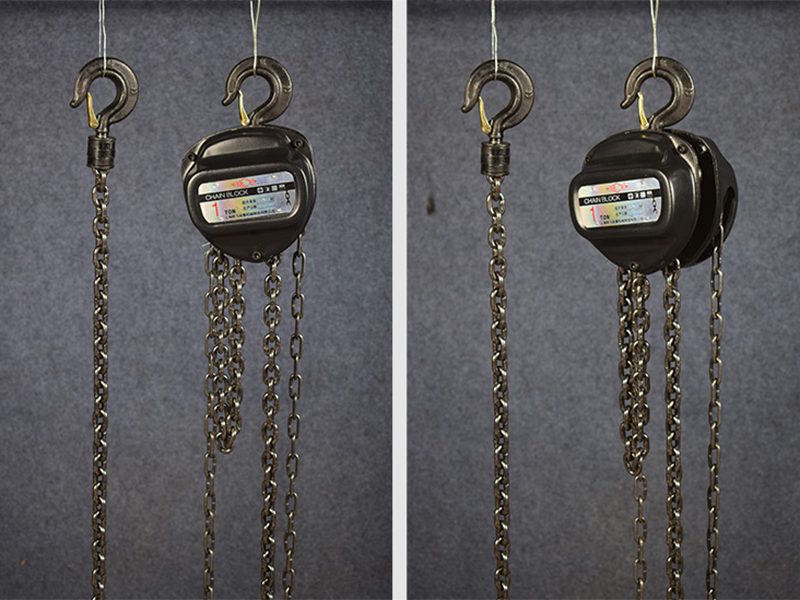

Triangle Chain Hoist

Working Principle

The working principle of a triangular chain hoist is similar to that of a circular chain hoist, mainly by manually operating the chain to lift heavy objects. Specifically, a chain hoist is mainly composed of manual chains, hand chain wheels, ratchet wheels, gear sets, and other components. When the operator pulls the manual chain, the hand chain wheel rotates accordingly, and through the transmission effect of the gear set, the lifting chain wheel is driven to rotate, thereby driving the lifting chain to lift heavy objects.

The advantage of triangular chain hoists over circular chain hoists is that their structure is more stable and durable. The triangular design makes the shell and internal parts more compact, reduces gaps, lowers the chance of dust entering, and is less likely to deform under external impact, thus better protecting the internal parts.

In addition, the triangular chain hoist is more labor-saving, operates more smoothly, and has a longer service life during use.

Scope of Use

The triangular chain hoist has a wide range of applications, mainly used in the following fields:

Factories, mines, docks, warehouses, construction sites, and agricultural production: In these places, triangular chain hoists are commonly used for lifting goods and hoisting equipment, especially in situations where there is no power supply or the site is small, demonstrating superiority.

In flammable and explosive places such as petroleum, chemical, refining, gas extraction, oil transportation, and mining operations, triangular chain hoists are widely used due to their explosion-proof design.

In outdoor workplaces without power supply, such as buildings, bridges, paving and road construction projects, triangular chain hoists are frequently used due to their manual operation characteristics.

The advantages of a triangular chain hoist include:

More stable structure: The structural design of the triangular chain hoist makes it more compact, reducing the gap between internal parts and the cover, and minimizing external damage to the interior of the chain hoist, thereby extending its service life.

Longer service life: Due to its compact structure, the internal parts are not easily damaged, significantly improving the service life.

Effortless operation: smoother to use, less pulling force, easier to operate and less prone to chain jamming.

Technical Parameters

Model |

|

National standard |

1T*3m |

National standard |

2T*3m |

National standard |

3T*3m |

National standard |

5T*3m |

National standard |

10T*3m |

National standard |

20T*3m |

National standard |

1T*6m |

National standard |

2T*6m |

National standard |

3T*6m |

National standard |

5T*6m |

National standard |

10T*6m |

National standard |

20T*6m |

National standard |

1T*9m |

National standard |

2T*9m |

National standard |

3T*9m |

National standard |

5T*9m |

National standard |

10T*9m |

Characteristics

Lifting height: 3m

Standard lifting height: 3m

Increase speed: 3m/min

Chain diameter: 6mm

Minimum distance between two hooks: 185mm

Rated lifting capacity: 1000Kg

Net weight: 10Kg

Load: 1250Kg

Triangle chain hoist

Thickened casing

Strong power

Manganese steel chain

Application scope

1 Tons

2 Tons

3 Tons

5 Tons