Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the ever-evolving landscape of construction, safety remains a paramount concern for workers and project managers alike. The introduction of advanced technologies has significantly contributed to enhancing safety standards on job sites. One such innovation is the Electric Hoist Scaffold, a versatile and efficient lifting solution that transforms traditional scaffolding practices. By integrating electric hoisting mechanisms into scaffold systems, this technology not only streamlines the construction process but also minimizes risks associated with manual lifting and positioning of materials.

The Electric Hoist Scaffold is designed to elevate construction efficiency while prioritizing worker safety. Its unique features allow for greater control and stability, reducing the likelihood of accidents that often arise from improper handling of heavy loads. With its capability to effortlessly transport materials to varying heights, the Electric Hoist Scaffold mitigates fatigue and strain on workers, ensuring that they can focus on their tasks in a safer environment. As the construction industry embraces this innovative tool, the importance of safeguarding workers and enhancing operational productivity becomes more crucial than ever.

An electric hoist scaffold is an innovative construction tool designed to elevate workers and materials safely and efficiently. This system combines the functions of a scaffold with an electric hoist, allowing for the smooth lifting and lowering of loads to various heights. The structure typically consists of secure platforms supported by a frame, which can be adjusted to accommodate different building elevations. With the integration of an electric hoist, the process of moving heavy materials becomes significantly easier, reducing the physical strain on workers and enhancing productivity on job sites.

The design of electric hoist scaffolds emphasizes safety and stability. Equipped with control mechanisms, these scissor lifts and suspended platforms ensure precise movements that minimize the risk of accidents. Workers can operate the hoist from a secure position, allowing them to focus on their tasks without the constant worry of injuries due to manual lifting. Additionally, many electric hoist scaffolds come with safety features such as load limits and emergency stop functions, further promoting a secure working environment. By incorporating these advanced systems into construction practices, projects can benefit from improved workflow and enhanced safety protocols.

Electric hoist scaffolds are designed to improve efficiency and safety in construction projects. These scaffolds incorporate several key components that contribute to their functionality. One of the most critical parts is the electric hoist system, which allows workers to lift and lower heavy materials with ease. This lowers the risk of manual handling injuries and increases productivity by enabling quick transportation of tools and supplies to various working heights.

Another essential component is the scaffold structure itself, which is built from durable materials to ensure stability and safety under heavy loads. Safety features such as guardrails and toe boards can be integrated into the design to prevent falls and protect workers. Additionally, electric hoist scaffolds often include control systems that enable operators to manage the hoisting process smoothly and safely, further enhancing the overall safety on the job site.

By incorporating these key components, electric hoist scaffolds not only streamline construction processes but also create a safer working environment for construction personnel. The combination of robust structures and advanced hoisting systems establishes a reliable framework that minimizes hazards, ultimately leading to higher standards of safety in the construction industry.

| Component | Description | Safety Features | Benefits |

|---|---|---|---|

| Electric Hoist | Lifts and lowers scaffolding materials and personnel. | Overload protection, automatic shut-off. | Increased lifting efficiency, reduced manual labor. |

| Scaffold Platform | The surface on which workers stand and work. | Anti-slip surface, guardrails. | Stability and support for workers, preventing falls. |

| Control System | Manages the hoist and movement of the scaffold. | Emergency stop, user-friendly interface. | Enhanced control for operators, rapid response in emergencies. |

| Safety Locking Mechanism | Prevents accidental lowering of the scaffold. | Fail-safe design, indicator lights. | Accident prevention, increased worker confidence. |

Electric hoist scaffolds are revolutionizing the construction industry by providing enhanced safety and efficiency. One of the primary advantages of these systems is their ability to lift heavy materials with ease, minimizing the risk of manual lifting injuries. By utilizing electric power, workers can quickly move materials to elevated areas, reducing the time spent on manual transport and allowing for quicker project completion.

Safety is further enhanced through the design of electric hoist scaffolds, which often come equipped with built-in safety features such as overload protection and emergency stop buttons. This ensures that workers can operate the equipment confidently, reducing the likelihood of accidents on site. Additionally, the stability and reliability of electric hoists contribute to a safer working environment, as they can handle materials in a controlled manner, decreasing the chance of dropped items that could cause injuries.

Tips for Using Electric Hoist Scaffolds Safely:

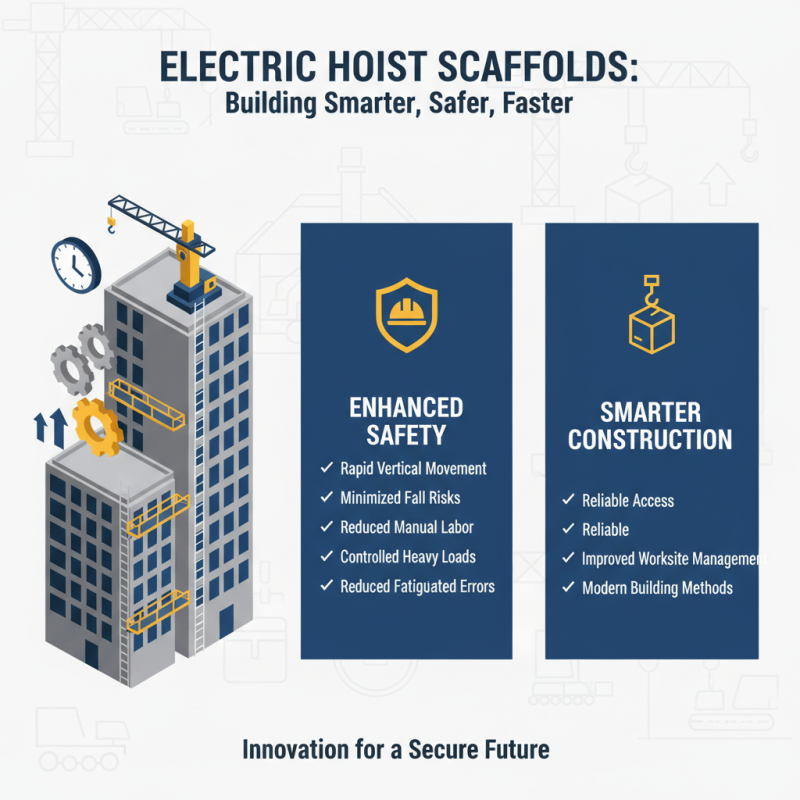

Electric hoist scaffolds represent a significant advancement in construction methods, offering not only increased efficiency but also enhanced safety standards on job sites. These systems enable the rapid and reliable vertical movement of workers and materials, reducing the need for manual lifting and minimizing the risks associated with traditional scaffolding methods. By integrating electric hoists, construction teams can better manage heavy loads, thereby decreasing the likelihood of accidents caused by dropped materials or fatigue-related errors.

The impact of electric hoist scaffolds on safety standards is profound. Improved stability and secure lifting mechanisms help to protect workers from falls, one of the leading causes of injuries in construction settings. Furthermore, the ability to elevate materials directly to the work area lessens the need for workers to climb scaffolds while carrying heavy items, which can lead to dangerous situations. Electric hoist scaffolds can also be equipped with safety features such as overload protection and automatic shut-off systems, further ensuring that safety protocols are strictly upheld. Overall, the implementation of electric hoist scaffolds enhances not only operational efficiency but also sets a higher benchmark for safety practices within the construction industry.

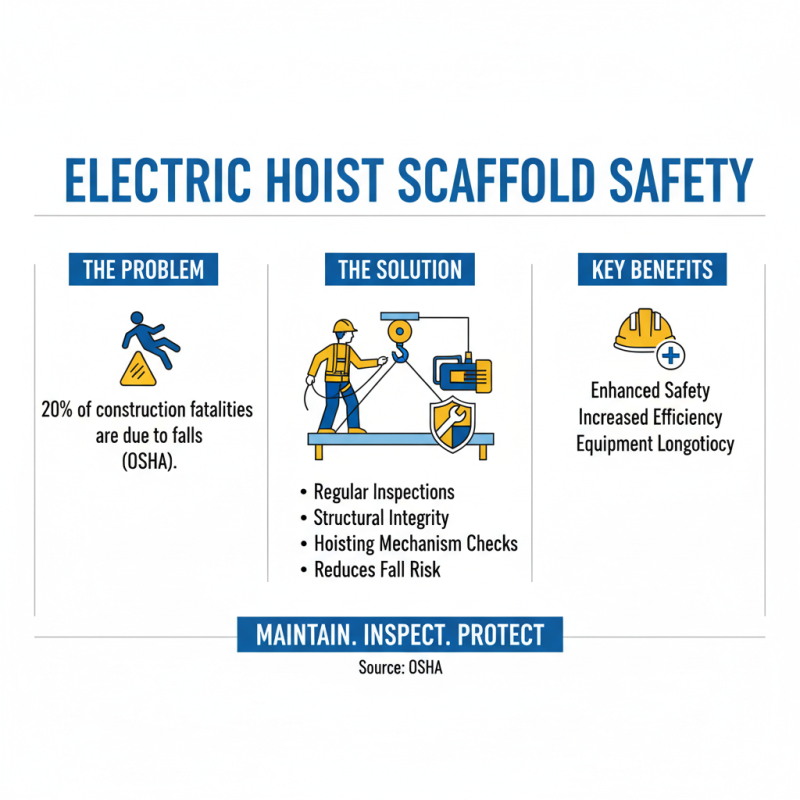

Electric hoist scaffolds are increasingly recognized for their role in enhancing construction safety. To maintain their effectiveness and ensure the safety of workers, it's crucial to follow strict maintenance and safety practices. According to the Occupational Safety and Health Administration (OSHA), approximately 20% of construction worker fatalities are due to falls, making the integrity of scaffolding systems vital. Regular inspections are essential, where professionals should check for structural integrity, wear and tear, and proper functionality of the hoisting mechanisms.

Moreover, implementing a routine maintenance schedule can significantly mitigate risks. The American National Standards Institute (ANSI) recommends monthly inspections along with maintenance checks after every major use. Proper training of personnel on how to safely operate electric hoist scaffolds also plays a critical role in enhancing safety. Research indicates that well-trained workers are 40% less likely to be involved in accidents related to scaffold operations. Therefore, adhering to maintenance protocols, conducting frequent inspections, and ensuring comprehensive worker training is paramount in fostering a safer construction environment.